Table of Contents

Benefits of Using Fully Auto Can Sealing Machine for EOE Lid

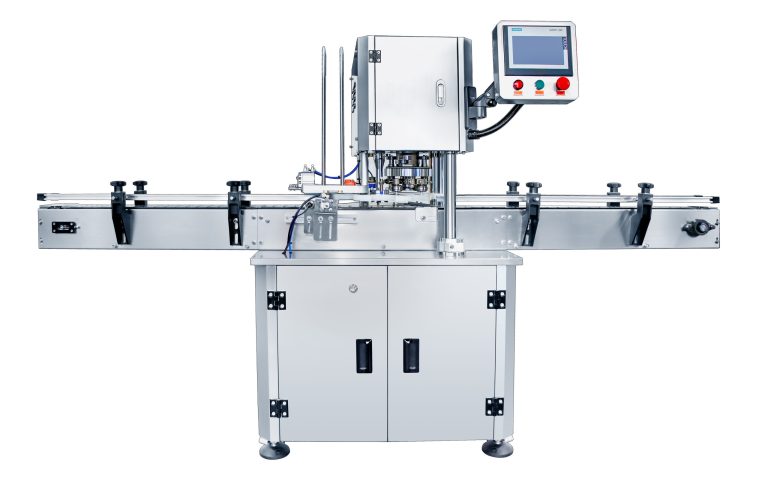

In the food and beverage industry, packaging plays a crucial role in ensuring the quality and safety of products. One of the most common types of packaging used for canned goods is the easy-open end (EOE) lid. These lids are designed to provide consumers with convenient access to the contents of the can while also maintaining the freshness and integrity of the product. To seal these EOE lids onto cans efficiently and effectively, many manufacturers rely on fully automatic can sealing machines.

Fully automatic can sealing machines offer a range of benefits for businesses looking to streamline their packaging processes. One of the key advantages of using a fully automatic machine is the speed and efficiency it provides. These machines are capable of sealing hundreds of cans per minute, significantly increasing production output and reducing labor costs. By automating the sealing process, manufacturers can achieve higher levels of productivity and meet the demands of a fast-paced production environment.

In addition to speed, fully automatic can sealing machines also offer consistent and precise sealing results. These machines are equipped with advanced technology that ensures each lid is sealed securely onto the can with the right amount of pressure and heat. This level of precision helps to minimize the risk of leaks or contamination, ensuring that products remain fresh and safe for consumers. By maintaining a high level of quality control, businesses can build trust with their customers and protect their brand reputation.

Another benefit of using a fully automatic can sealing machine is the versatility it provides. These machines are designed to accommodate a wide range of can sizes and lid types, making them suitable for a variety of packaging needs. Whether a manufacturer is producing small cans of fruit or large cans of soup, a fully automatic machine can be easily adjusted to meet different requirements. This flexibility allows businesses to adapt to changing market demands and expand their product offerings without investing in additional equipment.

-scaled.jpg)

Furthermore, fully automatic can sealing machines are also known for their durability and reliability. These machines are built to withstand the rigors of continuous use in a production setting, ensuring long-term performance and minimal downtime. By investing in a high-quality machine, manufacturers can reduce maintenance costs and avoid costly repairs that can disrupt production schedules. With proper care and maintenance, a fully automatic can sealing machine can provide years of reliable service, making it a valuable asset for any packaging operation.

In conclusion, the benefits of using a fully automatic can sealing machine for EOE lid are clear. From increased speed and efficiency to consistent sealing results and versatility, these machines offer a range of advantages for businesses looking to optimize their packaging processes. By investing in a fully automatic machine, manufacturers can improve productivity, ensure product quality, and enhance their overall competitiveness in the market. With the right equipment in place, businesses can meet the demands of today’s consumers and achieve long-term success in the food and beverage industry.

How to Choose the Right Fully Auto Can Sealing Machine for EOE Lid

When it comes to packaging food products, a fully automatic can sealing machine for EOE lids is an essential piece of equipment for any food processing facility. These machines are designed to efficiently seal cans with easy-open (EOE) lids, ensuring that the contents remain fresh and protected from external contaminants. However, with so many options available on the market, choosing the right fully automatic can sealing machine can be a daunting task. In this article, we will discuss some key factors to consider when selecting a fully auto can sealing machine for EOE lids.

First and foremost, it is important to consider the production capacity of the machine. Different machines are designed to handle varying levels of production, so it is crucial to choose a machine that can meet the demands of your facility. Consider factors such as the number of cans per minute that the machine can seal, as well as the size and type of cans that it can accommodate. Additionally, consider the size of your facility and the available space for the machine, as some fully automatic can sealing machines can be quite large and require ample space for operation.

Another important factor to consider when choosing a fully auto can sealing machine for EOE lids is the level of automation and ease of use. Look for a machine that offers user-friendly controls and intuitive operation, as this will help to streamline the production process and minimize the risk of errors. Additionally, consider whether the machine offers features such as automatic lid feeding and positioning, as these can further enhance efficiency and productivity.

In addition to production capacity and automation, it is also important to consider the quality and reliability of the machine. Look for a fully automatic can sealing machine that is constructed from high-quality materials and components, as this will ensure durability and longevity. Additionally, consider the reputation of the manufacturer and look for machines that come with a warranty or guarantee, as this can provide added peace of mind.

When choosing a fully auto can sealing machine for EOE lids, it is also important to consider the cost of the machine. While it is important to invest in a high-quality machine that meets the needs of your facility, it is also important to consider your budget and choose a machine that offers the best value for money. Compare prices from different manufacturers and consider factors such as maintenance and operating costs when making your decision.

In conclusion, choosing the right fully automatic can sealing machine for EOE lids is a crucial decision for any food processing facility. Consider factors such as production capacity, automation, quality, reliability, and cost when making your decision. By taking the time to carefully evaluate your options and choose a machine that meets your specific needs, you can ensure that your facility operates efficiently and effectively.

Maintenance Tips for Fully Auto Can Sealing Machine for EOE Lid

Maintaining a fully automatic can sealing machine for EOE lids is crucial to ensure its optimal performance and longevity. Regular maintenance not only helps prevent breakdowns and costly repairs but also ensures that the machine operates efficiently, producing high-quality sealed cans consistently. In this article, we will discuss some essential maintenance tips to keep your fully automatic can sealing machine in top condition.

One of the most important maintenance tasks for a fully automatic can sealing machine is regular cleaning. Dust, debris, and food particles can accumulate on the machine’s components, leading to malfunctions and decreased efficiency. It is recommended to clean the machine after each use, paying special attention to the sealing head, rollers, and conveyor belts. Use a soft brush or cloth to remove any buildup and ensure that all parts are dry before operating the machine again.

In addition to cleaning, lubricating the moving parts of the can sealing machine is essential to prevent wear and tear. Regularly check the lubrication levels of the machine’s bearings, gears, and other moving components, and apply the appropriate lubricant as needed. Over time, friction can cause these parts to wear out, leading to decreased performance and potential breakdowns. By keeping the machine properly lubricated, you can extend its lifespan and ensure smooth operation.

Another important maintenance tip for a fully automatic can sealing machine is to regularly inspect and replace worn or damaged parts. Check the machine’s seals, gaskets, and O-rings for signs of wear or deterioration, as these components are crucial for creating a tight seal on the cans. Replace any damaged parts immediately to prevent leaks and ensure the quality of the sealed cans. Additionally, inspect the machine’s electrical components, such as sensors and switches, for any signs of damage or malfunction, and replace them as needed.

Calibrating the machine’s settings is also essential for maintaining optimal performance. Over time, the machine’s settings may drift out of alignment, leading to inconsistent sealing results. Regularly check and adjust the machine’s settings, such as the sealing temperature, pressure, and speed, to ensure that it is operating within the specified parameters. This will help produce consistent and high-quality sealed cans, reducing the risk of product spoilage or contamination.

Lastly, it is important to schedule regular maintenance checks with a qualified technician to ensure that your fully automatic can sealing machine is in good working condition. A professional technician can inspect the machine thoroughly, identify any potential issues, and perform any necessary repairs or adjustments. Regular maintenance checks can help prevent unexpected breakdowns and ensure that the machine continues to operate efficiently.

In conclusion, proper maintenance is essential for keeping a fully automatic can sealing machine for EOE lids in top condition. By following these maintenance tips, you can ensure that your machine operates efficiently, produces high-quality sealed cans consistently, and lasts for years to come. Regular cleaning, lubrication, inspection, calibration, and professional maintenance checks are all key components of a comprehensive maintenance plan for your can sealing machine. By investing time and effort into maintaining your machine, you can avoid costly repairs and downtime, and ensure that your production line runs smoothly and efficiently.