Table of Contents

Benefits of Using Automatic Irregular Cans Sealing Machine in Food Packaging Industry

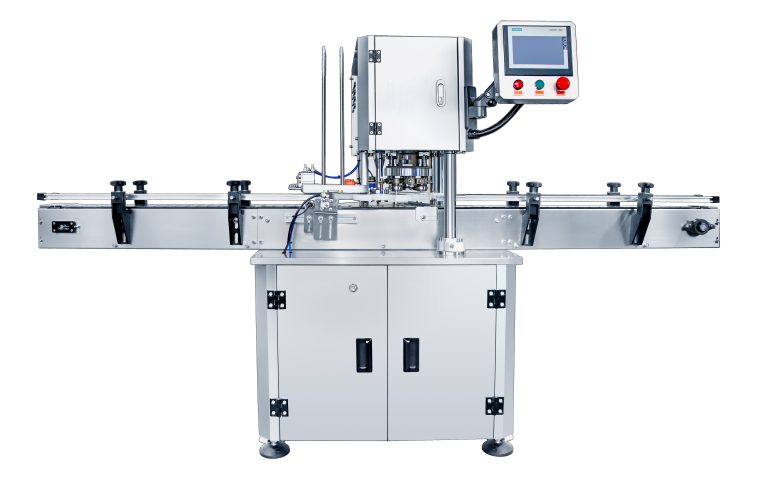

In the food packaging industry, efficiency and consistency are key factors in ensuring the quality and safety of products. One important aspect of food packaging is the sealing of cans, which helps to preserve the contents and prevent contamination. Traditional methods of sealing cans can be time-consuming and prone to human error, leading to inconsistencies in the sealing process. This is where automatic irregular cans sealing machines come into play, offering a range of benefits for food manufacturers.

One of the main advantages of using an automatic irregular cans sealing machine is the speed and efficiency it brings to the packaging process. These machines are designed to seal cans quickly and accurately, reducing the time and labor required for manual sealing. This not only increases productivity but also ensures a consistent seal on every can, minimizing the risk of leaks or contamination.

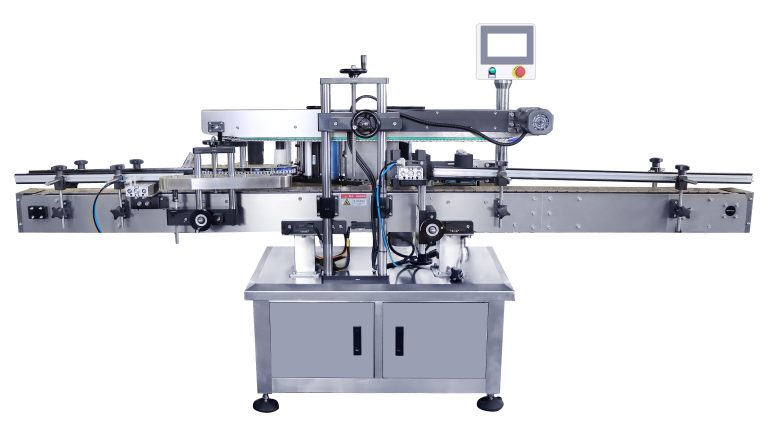

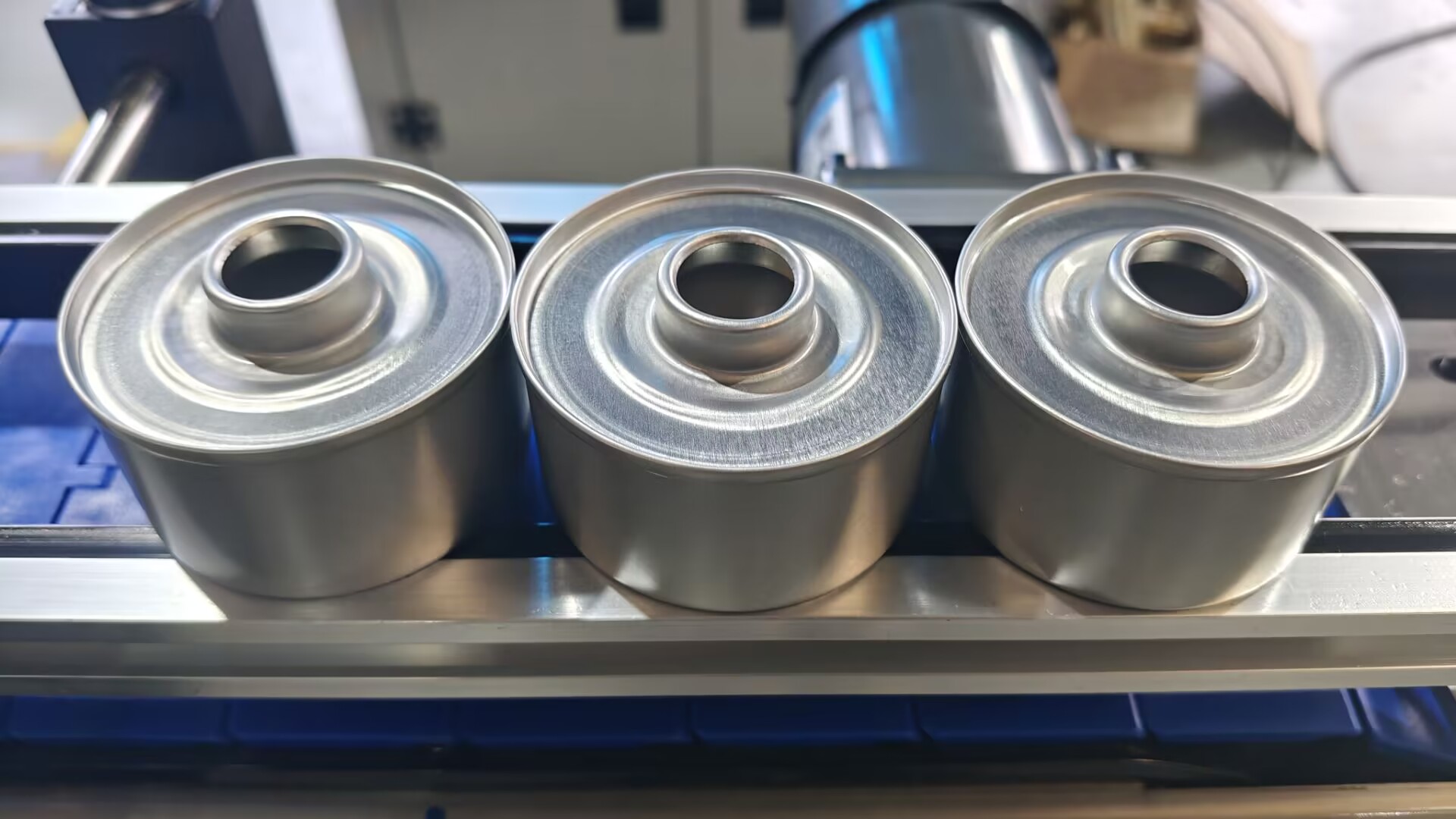

Another benefit of automatic irregular cans sealing machines is their versatility. These machines are capable of sealing cans of various shapes and sizes, making them ideal for a wide range of food products. Whether you are packaging soups, sauces, or beverages, an automatic irregular cans sealing machine can accommodate your needs, saving you time and effort in the packaging process.

In addition to speed and versatility, automatic irregular cans sealing machines also offer improved safety and hygiene in the packaging process. By automating the sealing process, these machines reduce the risk of human error and contamination, ensuring that your products meet the highest standards of quality and safety. This is especially important in the food industry, where strict regulations govern the packaging and handling of products.

Furthermore, automatic irregular cans sealing machines are designed to be easy to use and maintain, making them a cost-effective solution for food manufacturers. These machines require minimal training to operate and can be easily integrated into existing production lines. Additionally, they are built to withstand the rigors of continuous use, reducing the need for frequent repairs or replacements.

Overall, the benefits of using an automatic irregular cans sealing machine in the food packaging industry are clear. From increased efficiency and consistency to improved safety and hygiene, these machines offer a range of advantages for food manufacturers looking to streamline their packaging process. By investing in an automatic irregular cans sealing machine, you can ensure that your products are sealed securely and efficiently, meeting the highest standards of quality and safety.

How to Choose the Right Automatic Irregular Cans Sealing Machine for Your Production Line

In the world of manufacturing, efficiency and precision are key factors in ensuring a successful production line. When it comes to sealing irregular cans, having the right equipment can make all the difference. Automatic irregular cans sealing machines are designed to streamline the sealing process, saving time and reducing the risk of errors. However, with so many options available on the market, choosing the right machine for your production line can be a daunting task.

One of the first things to consider when selecting an automatic irregular cans sealing machine is the size and shape of the cans you will be working with. Different machines are designed to accommodate different sizes and shapes of cans, so it is important to choose a machine that can handle the specific requirements of your production line. Additionally, consider the speed at which the machine can operate. Some machines are capable of sealing hundreds of cans per minute, while others may have a slower output. Assessing your production needs will help you determine the appropriate speed for your machine.

Another important factor to consider is the type of sealing method used by the machine. There are several different sealing methods available, including induction sealing, hot air sealing, and vacuum sealing. Each method has its own advantages and disadvantages, so it is important to choose a machine that uses a sealing method that is best suited to your production line. Additionally, consider the level of automation offered by the machine. Some machines are fully automated, while others may require manual intervention at certain points in the sealing process. Choosing a machine with the right level of automation can help improve efficiency and reduce the risk of errors.

When selecting an automatic irregular cans sealing machine, it is also important to consider the overall build quality and durability of the machine. Look for machines that are made from high-quality materials and are built to withstand the rigors of continuous use. Additionally, consider the reputation of the manufacturer. Choose a machine from a reputable manufacturer with a track record of producing reliable and high-quality equipment.

Finally, consider the cost of the machine. Automatic irregular cans sealing machines can vary widely in price, so it is important to set a budget and stick to it. Keep in mind that while a more expensive machine may offer additional features and capabilities, a less expensive machine may still meet your production needs. Consider the long-term costs of operating the machine, including maintenance and repair costs, when making your decision.

In conclusion, choosing the right automatic irregular cans sealing machine for your production line is a crucial decision that can have a significant impact on the efficiency and success of your manufacturing operation. Consider factors such as the size and shape of the cans, the speed and sealing method of the machine, the level of automation, the build quality and durability, the reputation of the manufacturer, and the cost of the machine. By carefully evaluating these factors and selecting a machine that meets your specific requirements, you can ensure that your production line runs smoothly and efficiently.