Table of Contents

Benefits of Investing in an Automatic Fruit Drink Beverage Can Filling Seaming Labeling Machine Packaging Line

Investing in an automatic fruit drink beverage can filling seaming labeling machine packaging line can bring numerous benefits to your business. These machines are designed to streamline the production process, increase efficiency, and improve overall product quality. In this article, we will explore the various advantages of investing in this advanced packaging technology.

One of the key benefits of an automatic fruit drink beverage can filling seaming labeling machine packaging line is its ability to increase production speed. These machines are capable of filling and sealing hundreds of cans per minute, significantly reducing the time it takes to package your products. This increased efficiency can help you meet customer demand more effectively and improve your overall productivity.

In addition to speeding up production, automatic packaging lines can also help improve product quality. These machines are designed to fill and seal cans with precision, ensuring that each product is packaged consistently and accurately. This can help reduce the risk of errors and defects, leading to a higher quality end product that meets customer expectations.

Another advantage of investing in an automatic packaging line is the cost savings it can provide. While the initial investment in these machines may be significant, the long-term savings can be substantial. By increasing production speed and efficiency, you can reduce labor costs and minimize waste, ultimately improving your bottom line.

Furthermore, automatic packaging lines can also help improve workplace safety. By automating the packaging process, you can reduce the risk of injuries and accidents that can occur when employees are manually filling and sealing cans. This can create a safer work environment for your employees and help you comply with industry regulations.

In addition to these practical benefits, investing in an automatic packaging line can also help enhance your brand image. By using advanced technology to package your products, you can convey a sense of professionalism and quality to your customers. This can help build trust and loyalty among your target audience, ultimately leading to increased sales and revenue.

Overall, investing in an automatic fruit drink beverage can filling seaming labeling machine packaging line can bring numerous benefits to your business. From increased production speed and efficiency to improved product quality and cost savings, these machines can help you take your packaging process to the next level. By embracing this advanced technology, you can position your business for success in a competitive market and drive growth for years to come.

How to Choose the Right Automatic Fruit Drink Beverage Can Filling Seaming Labeling Machine Packaging Line for Your Business

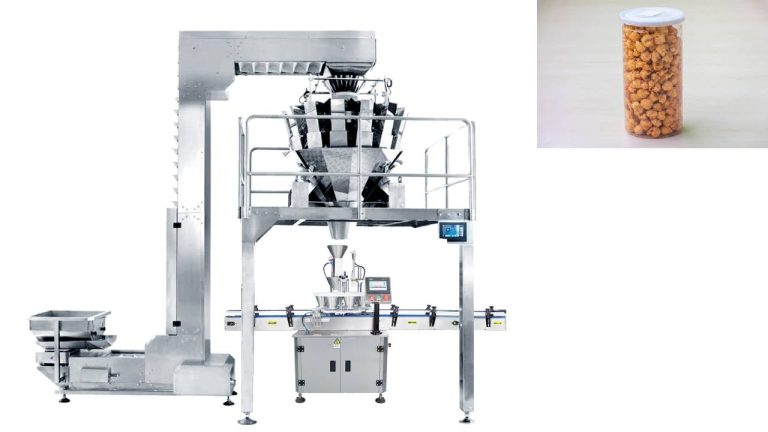

In the world of beverage packaging, efficiency and precision are key factors in ensuring a successful production line. When it comes to filling, seaming, and labeling fruit drink beverage cans, choosing the right automatic packaging line is crucial for meeting production goals and maintaining product quality. With a wide range of options available on the market, it can be overwhelming to select the best machine for your business needs. In this article, we will discuss some important factors to consider when choosing an automatic fruit drink beverage can filling seaming labeling machine packaging line.

First and foremost, it is essential to consider the production capacity of the machine. Different machines have varying capacities, ranging from a few hundred cans per hour to several thousand cans per hour. Understanding your production requirements is crucial in selecting a machine that can meet your output goals without causing bottlenecks in the production line. Additionally, consider the flexibility of the machine in terms of adjusting filling volumes and can sizes to accommodate different product variations.

Another important factor to consider is the level of automation of the machine. Automatic packaging lines can range from semi-automatic machines that require some manual intervention to fully automatic machines that operate with minimal human involvement. Depending on your production needs and budget, choose a machine that strikes the right balance between automation and manual operation. Fully automatic machines are ideal for high-volume production lines where consistency and efficiency are paramount.

In addition to production capacity and automation level, it is crucial to consider the quality and reliability of the machine. Look for machines from reputable manufacturers with a track record of producing high-quality equipment. Check for certifications and compliance with industry standards to ensure that the machine meets safety and quality requirements. Investing in a reliable machine may require a higher upfront cost, but it will pay off in the long run by minimizing downtime and maintenance costs.

Furthermore, consider the space requirements of the machine and its compatibility with your existing production line. Automatic packaging lines come in various sizes and configurations, so make sure to measure the available space in your facility and choose a machine that fits seamlessly into your production layout. Additionally, ensure that the machine is compatible with other equipment in your production line to avoid compatibility issues and ensure smooth operation.

Lastly, consider the after-sales support and service provided by the manufacturer. A reliable manufacturer should offer technical support, spare parts availability, and maintenance services to ensure that your machine operates smoothly and efficiently. Look for manufacturers with a strong customer service reputation and a responsive support team to address any issues that may arise during operation.

In conclusion, choosing the right automatic fruit drink beverage can filling seaming labeling machine packaging line is a critical decision that can impact the efficiency and success of your production line. Consider factors such as production capacity, automation level, quality and reliability, space requirements, and after-sales support when selecting a machine for your business. By carefully evaluating these factors and choosing a machine that meets your specific needs, you can ensure a smooth and efficient production process for your fruit drink beverage cans.