It seems we can’t find what you’re looking for. Perhaps searching can help.

What types of products can be packaged using a can seaming machine?

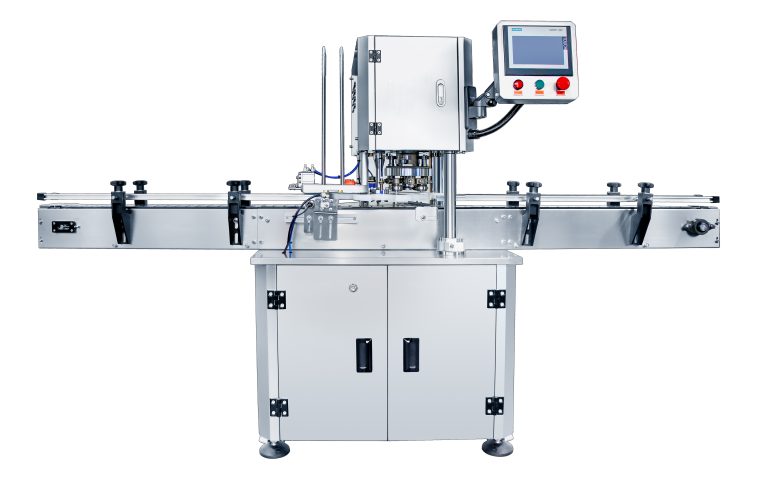

Food Products A can seaming machine is a versatile piece of equipment that is commonly used in the food industry to package a wide variety of products. This machine is designed to seal cans by creating a hermetic seal between the lid and the body of the can, ensuring that…