Table of Contents

Advantages of Using Plastic Jars Snap Capper Equipment in Manufacturing Processes

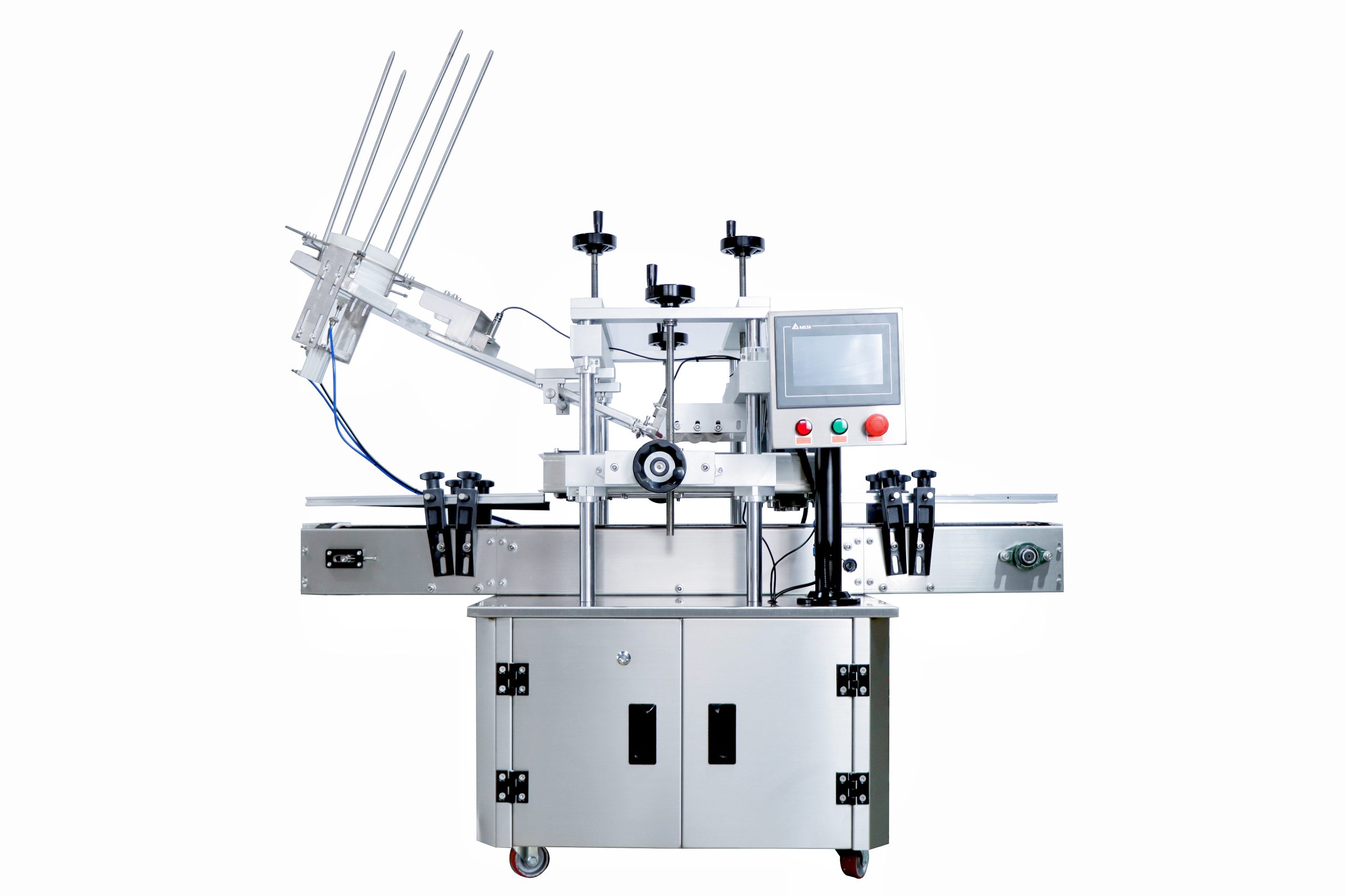

Plastic jars snap capper equipment has become an essential tool in the manufacturing industry, especially for companies that produce a large volume of products in plastic jars. These machines are designed to efficiently seal plastic jars with snap-on caps, ensuring a secure and airtight closure. There are several advantages to using plastic jars snap capper equipment in manufacturing processes, which we will explore in this article.

One of the primary benefits of using plastic jars snap capper equipment is the speed and efficiency it brings to the production process. These machines are capable of sealing hundreds of jars per minute, significantly increasing the output of a manufacturing line. This not only saves time but also reduces labor costs, as fewer workers are needed to manually seal each jar.

In addition to speed, plastic jars snap capper equipment also ensures consistency in the sealing process. Each jar is sealed with the same amount of pressure and precision, resulting in a uniform and professional-looking finished product. This consistency is crucial for maintaining the quality of the product and meeting customer expectations.

Another advantage of using plastic jars snap capper equipment is the reduction of waste. Manual sealing processes can lead to errors and inconsistencies, resulting in a higher rate of defective products that need to be discarded. By automating the sealing process, manufacturers can minimize waste and improve overall efficiency.

Furthermore, plastic jars snap capper equipment is versatile and can be easily adjusted to accommodate different jar sizes and cap types. This flexibility allows manufacturers to quickly switch between products without the need for extensive retooling or downtime. This is especially beneficial for companies that produce a variety of products in different packaging formats.

In addition to efficiency and versatility, plastic jars snap capper equipment also helps improve workplace safety. Manual sealing processes can be repetitive and physically demanding, leading to potential injuries and strain on workers. By automating the sealing process, manufacturers can create a safer work environment and reduce the risk of workplace accidents.

Overall, the use of plastic jars snap capper equipment in manufacturing processes offers numerous benefits, including increased speed, consistency, waste reduction, versatility, and improved workplace safety. These machines are a valuable investment for companies looking to streamline their production processes and enhance the quality of their products.

In conclusion, plastic jars snap capper equipment has revolutionized the way manufacturers seal plastic jars, offering a range of advantages that contribute to increased efficiency, consistency, and overall product quality. By investing in this technology, companies can improve their production processes, reduce waste, and create a safer work environment for their employees.

How to Choose the Right Plastic Jars Snap Capper Equipment Manufacturer for Your Business

Plastic jars snap capper equipment is essential for businesses in the packaging industry. These machines are designed to securely seal plastic jars with snap-on lids, ensuring that products remain fresh and protected during storage and transportation. Choosing the right plastic jars snap capper equipment manufacturer is crucial for ensuring the efficiency and reliability of your packaging process.

When selecting a plastic jars snap capper equipment manufacturer for your business, there are several factors to consider. First and foremost, you should look for a manufacturer with a solid reputation for producing high-quality equipment. This can be determined by researching the manufacturer’s track record, reading customer reviews, and checking for any certifications or awards they may have received.

Additionally, it is important to consider the manufacturer’s experience and expertise in the industry. A manufacturer with years of experience in producing plastic jars snap capper equipment is more likely to have the knowledge and skills necessary to meet your specific needs and requirements. They will also be better equipped to provide you with expert advice and guidance on selecting the right equipment for your business.

Another important factor to consider when choosing a plastic jars snap capper equipment manufacturer is the level of customer support and service they offer. A manufacturer that is responsive to your inquiries, provides timely assistance, and offers ongoing support and maintenance services will help ensure that your equipment operates smoothly and efficiently.

Furthermore, it is important to consider the cost of the equipment and whether it fits within your budget. While it may be tempting to opt for the cheapest option, it is important to remember that quality should not be compromised for the sake of saving money. Investing in high-quality equipment from a reputable manufacturer may cost more upfront but can save you money in the long run by reducing maintenance and repair costs.

In addition to these factors, you should also consider the manufacturer’s production capacity and lead times. A manufacturer with a large production capacity and quick lead times will be able to fulfill your orders in a timely manner, helping you meet your production deadlines and keep up with customer demand.

Overall, choosing the right plastic jars snap capper equipment manufacturer for your business is a decision that should not be taken lightly. By considering factors such as reputation, experience, customer support, cost, and production capacity, you can ensure that you select a manufacturer that meets your needs and helps you achieve your packaging goals. With the right equipment and manufacturer by your side, you can streamline your packaging process, improve efficiency, and deliver high-quality products to your customers.