Table of Contents

Introduction

Chili sauce, with its fiery flavor and diverse culinary applications, has a special place in the food industry. Packaging this zesty condiment properly is crucial to maintain its quality and appeal. Semi – auto vacuum capping for chili sauce glass jars is a remarkable solution that brings a host of benefits to the table. Let’s embark on a journey to uncover the wonders of this innovative packaging method.

Preserving the Essence of Chili Sauce

Locking in Freshness

One of the most significant advantages of semi – auto vacuum capping is its ability to preserve the freshness of chili sauce. When chili sauce is exposed to air, oxidation occurs. This can cause the sauce to lose its vibrant color, distinct aroma, and spicy kick. By creating a vacuum inside the glass jar during the capping process, the amount of oxygen is significantly reduced. As a result, the chili sauce retains its original flavor profile for a much longer time. For instance, a jar of chili sauce vacuum – capped using this method can maintain its fresh taste and aroma for months, ensuring that consumers enjoy the same high – quality product every time they open a jar.

Preventing Spoilage

Vacuum capping also acts as a powerful barrier against spoilage. Bacteria, mold, and other microorganisms thrive in the presence of oxygen. In a vacuum – sealed environment, their growth is severely inhibited. This is especially important for chili sauce, which often contains natural ingredients that can be prone to spoilage. With semi – auto vacuum capping, the risk of spoilage is minimized, extending the shelf life of the product and reducing waste for both manufacturers and consumers.

Ensuring Product Integrity

Consistent Sealing Quality

Semi – auto vacuum capping machines are designed to provide consistent sealing quality. These machines use precise mechanisms to apply the right amount of pressure and create a proper vacuum seal on each glass jar. Unlike manual capping, which can be subject to human error, the semi – auto process ensures that every jar is sealed to the same high standard. This consistency is vital for maintaining the reputation of the chili sauce brand and ensuring customer satisfaction.

Protecting Against Leakage

A well – sealed glass jar is essential to prevent leakage. Chili sauce is a viscous liquid that can be messy if it leaks out of the jar. Semi – auto vacuum capping creates a tight seal that effectively prevents any leakage during storage, transportation, and handling. This not only keeps the product clean and presentable but also reduces the risk of damage to other products in the packaging and shipping process.

Enhancing Production Efficiency

Streamlined Operation

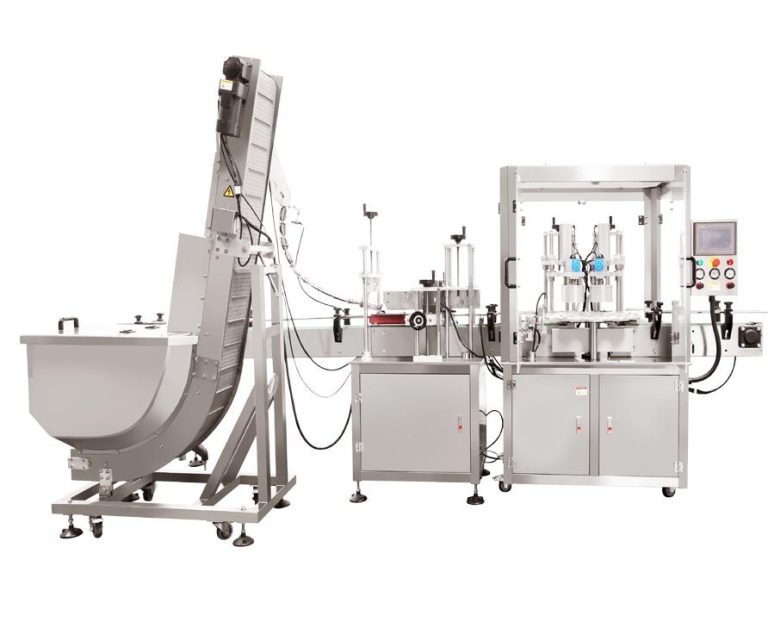

Semi – auto vacuum capping offers a balance between manual and fully automated processes. Operators can easily place the glass jars on the machine and initiate the capping process. The machine then takes over to create the vacuum and seal the jars. This streamlined operation reduces the time and effort required for capping compared to a fully manual method. As a result, manufacturers can increase their production output without sacrificing quality.

Quick Changeover for Different Jars

Chili sauce manufacturers often produce their products in various glass jar sizes and shapes. Semi – auto vacuum capping machines are designed to be adaptable. They can be easily adjusted to accommodate different jar dimensions. This quick changeover feature allows manufacturers to switch between different product lines efficiently, saving time and resources.

Cost – Effective Packaging Solution

Lower Equipment Investment

Compared to fully automated vacuum capping systems, semi – auto machines generally require a lower initial investment. This makes them an attractive option for small and medium – sized chili sauce producers who may have budget constraints. Despite the lower cost, semi – auto machines still offer many of the benefits of their automated counterparts, such as vacuum sealing and consistent quality.

Reduced Labor Costs

While semi – auto machines do require some operator involvement, they significantly reduce the amount of labor needed for capping. Fewer operators are required to achieve the same level of production compared to a fully manual capping process. This leads to cost savings in terms of labor wages, making semi – auto vacuum capping a cost – effective choice for chili sauce manufacturers.

Conclusion

Semi – auto vacuum capping for chili sauce glass jars is truly a wonder in the world of food packaging. It preserves the freshness and integrity of the chili sauce, enhances production efficiency, and offers a cost – effective solution for manufacturers. By embracing this technology, chili sauce producers can ensure that their products reach consumers in the best possible condition, delighting taste buds and building brand loyalty.

-768x622.jpg)