Benefits of Using an Automatic Coffee Beans Tinplate Can Filling and Sealing Line

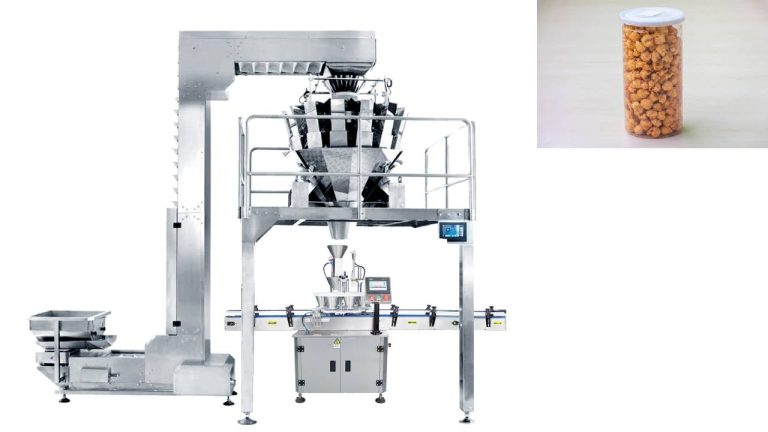

In the world of coffee production, efficiency and consistency are key factors in ensuring a high-quality product. One way to achieve this is by using an automatic coffee beans tinplate can filling and sealing line. This advanced technology offers a range of benefits that can help coffee producers streamline their operations and improve the overall quality of their products.

One of the primary benefits of using an automatic coffee beans tinplate can filling and sealing line is the increased efficiency it provides. These machines are designed to fill and seal cans at a much faster rate than manual methods, allowing producers to increase their output and meet growing demand. This can be especially beneficial for large-scale coffee producers who need to package and distribute large quantities of coffee beans quickly and efficiently.

In addition to increased efficiency, automatic filling and sealing lines also offer improved accuracy and consistency. These machines are programmed to fill each can with the exact amount of coffee beans, ensuring that every package is uniform and meets the same high standards of quality. This level of precision is difficult to achieve with manual filling methods, which can lead to inconsistencies in product quality and customer dissatisfaction.

Another key benefit of using an automatic coffee beans tinplate can filling and sealing line is the reduction of labor costs. By automating the filling and sealing process, producers can significantly reduce the need for manual labor, saving both time and money. This can be especially advantageous for small to medium-sized coffee producers who may not have the resources to hire a large workforce.

Furthermore, automatic filling and sealing lines can also help improve the overall safety and hygiene of the production process. These machines are designed to operate in a controlled environment, minimizing the risk of contamination and ensuring that the coffee beans remain fresh and free from impurities. This can be crucial for maintaining the quality and integrity of the product, as well as meeting strict food safety regulations.

Additionally, automatic filling and sealing lines are highly versatile and can be customized to meet the specific needs of each producer. Whether you are packaging whole coffee beans, ground coffee, or flavored blends, these machines can be adjusted to accommodate different types of products and packaging sizes. This flexibility allows producers to adapt to changing market demands and expand their product offerings without having to invest in new equipment.

In conclusion, the benefits of using an automatic coffee beans tinplate can filling and sealing line are clear. From increased efficiency and accuracy to reduced labor costs and improved safety, these machines offer a range of advantages that can help coffee producers enhance their operations and deliver a superior product to consumers. By investing in this advanced technology, producers can stay ahead of the competition and continue to grow their business in the competitive coffee industry.

-768x512.jpg)