Table of Contents

Benefits of Using a Screw Capper Machine with Double Head

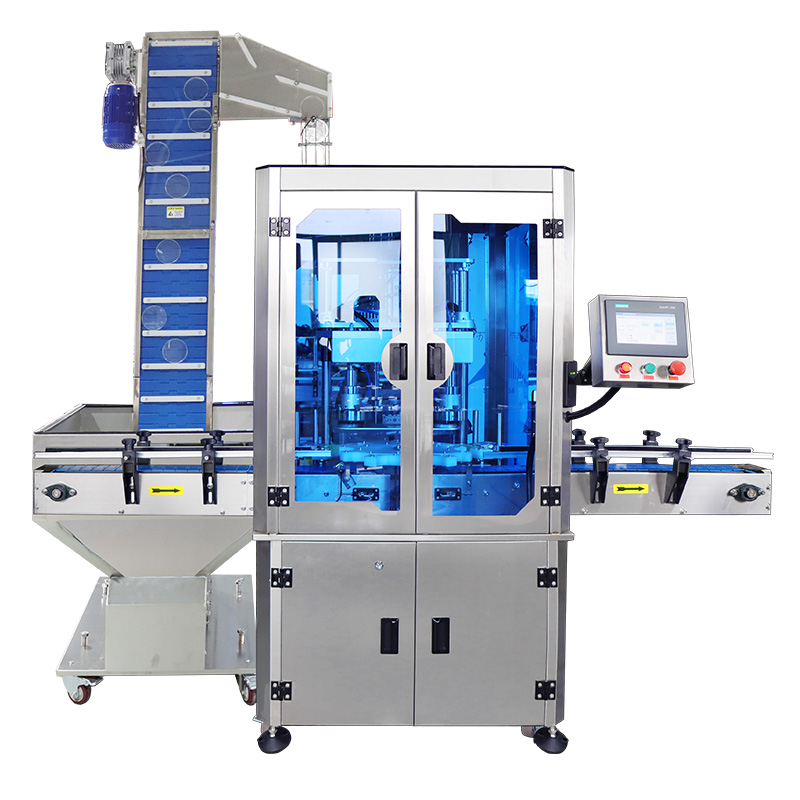

In the world of packaging and bottling, efficiency and speed are key factors in ensuring a successful production process. One machine that has revolutionized the industry is the screw capper machine with double head. This innovative piece of equipment offers a range of benefits that can greatly improve the efficiency and productivity of any bottling operation.

One of the primary advantages of using a screw capper machine with double head is its ability to cap two bottles simultaneously. This means that the machine can cap twice as many bottles in the same amount of time compared to a single head capper. This not only speeds up the production process but also reduces labor costs as fewer operators are needed to run the machine.

Furthermore, the double head design of the screw capper machine allows for greater flexibility in terms of bottle sizes and shapes. The machine can easily adjust to accommodate different bottle heights and diameters, making it suitable for a wide range of products. This versatility is especially beneficial for companies that produce multiple products with varying packaging requirements.

Another key benefit of using a screw capper machine with double head is its consistent and precise capping capabilities. The machine is equipped with advanced technology that ensures each bottle is capped securely and accurately every time. This helps to maintain product quality and integrity, as well as reduce the risk of leaks or contamination during storage and transportation.

In addition to its efficiency and precision, the screw capper machine with double head also offers a significant cost-saving advantage. By increasing production output and reducing labor costs, companies can achieve higher levels of profitability and competitiveness in the market. The machine’s durable construction and low maintenance requirements further contribute to its cost-effectiveness over the long term.

Moreover, the double head design of the screw capper machine allows for easy integration into existing bottling lines. The machine can be seamlessly connected to other equipment such as fillers, labelers, and conveyors, creating a streamlined and efficient production process. This integration not only saves space but also improves overall workflow and productivity.

Overall, the benefits of using a screw capper machine with double head are clear. From increased production output and cost savings to improved product quality and flexibility, this innovative piece of equipment offers a range of advantages that can greatly enhance the efficiency and productivity of any bottling operation. Companies looking to optimize their packaging processes and stay ahead of the competition should consider investing in a screw capper machine with double head.

How to Properly Maintain and Clean a Screw Capper Machine with Double Head

A screw capper machine with double head is a valuable piece of equipment for businesses in the packaging industry. This machine is designed to efficiently cap bottles with screw caps, ensuring a tight seal and preventing any leaks or contamination. To ensure the machine continues to operate at its best, proper maintenance and cleaning are essential.

Regular maintenance is key to keeping a screw capper machine with double head in good working condition. This includes checking for any loose or damaged parts, lubricating moving components, and inspecting the machine for any signs of wear and tear. By addressing any issues promptly, you can prevent more serious problems from occurring and extend the lifespan of the machine.

Cleaning the machine is also crucial to maintaining its performance. Over time, dust, debris, and residue from the capping process can build up on the machine, affecting its efficiency and potentially causing contamination. Regular cleaning helps to remove these contaminants and keep the machine running smoothly.

To properly clean a screw capper machine with double head, start by disconnecting the machine from power and removing any bottles or caps. Use a soft brush or cloth to remove any visible debris from the machine, paying special attention to the capping heads and conveyor belts. For stubborn residue, a mild detergent or cleaning solution can be used, but be sure to rinse the machine thoroughly to remove any cleaning agents.

After cleaning, it is important to lubricate the moving parts of the machine to ensure smooth operation. Use a food-grade lubricant recommended by the manufacturer, applying it sparingly to avoid excess buildup. Be sure to follow the manufacturer’s guidelines for lubrication intervals to prevent over-lubrication, which can attract dirt and debris.

In addition to regular maintenance and cleaning, it is important to follow proper operating procedures when using a screw capper machine with double head. This includes ensuring that the machine is set up correctly for the size and type of bottles being capped, as well as monitoring the capping process to detect any issues early on.

By following these maintenance and cleaning guidelines, you can keep your screw capper machine with double head in top condition and avoid costly repairs or downtime. Regular maintenance not only extends the lifespan of the machine but also ensures that it continues to cap bottles efficiently and effectively.

In conclusion, proper maintenance and cleaning are essential for keeping a screw capper machine with double head in good working condition. By following the manufacturer’s guidelines and regularly inspecting and cleaning the machine, you can prevent issues from arising and ensure that the machine continues to operate at its best. Investing time and effort into maintaining your screw capper machine will pay off in the long run, saving you money on repairs and downtime while ensuring that your packaging process runs smoothly and efficiently.