Table of Contents

Benefits of Using Fully Automatic Snacks Plastic Jar Screw Capping Machine

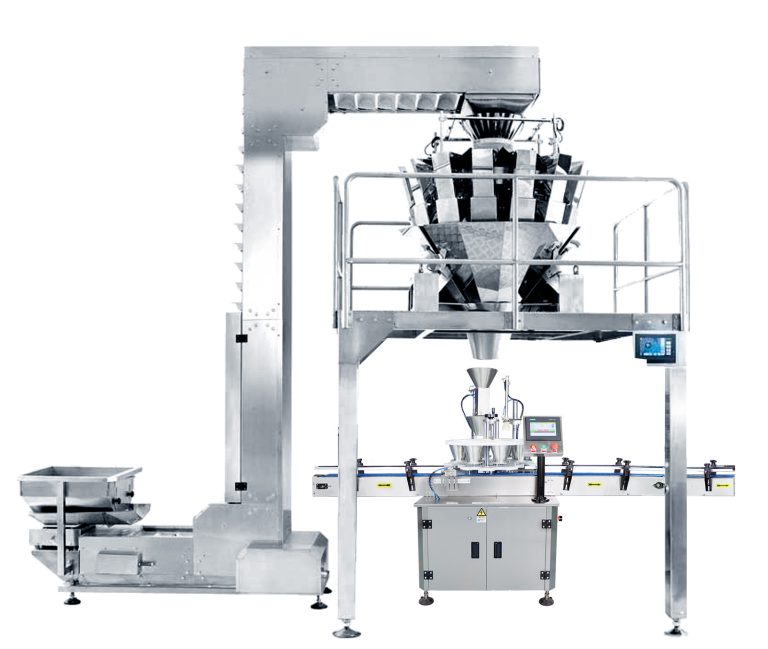

In the food industry, packaging plays a crucial role in maintaining the quality and freshness of products. Snacks, in particular, require efficient and reliable packaging solutions to ensure that they reach consumers in perfect condition. One of the key components of snack packaging is the screw cap, which seals the jar and prevents air and moisture from entering. To streamline this process, many snack manufacturers are turning to fully automatic snacks plastic jar screw capping machines.

These machines offer a range of benefits that can significantly improve the efficiency and productivity of snack packaging operations. One of the primary advantages of using a fully automatic screw capping machine is speed. These machines are capable of capping jars at a much faster rate than manual or semi-automatic methods. This increased speed not only allows manufacturers to meet high production demands but also helps reduce labor costs by minimizing the need for manual intervention.

Furthermore, fully automatic screw capping machines are designed to be highly accurate and consistent. This ensures that each jar is sealed with the correct amount of torque, preventing leaks and ensuring the freshness of the product. In addition, these machines are equipped with sensors and controls that can detect any issues with the capping process, such as misaligned caps or insufficient torque. This helps to minimize the risk of defective products reaching consumers and protects the reputation of the brand.

Another key benefit of using a fully automatic screw capping machine is versatility. These machines are capable of capping jars of various sizes and shapes, making them suitable for a wide range of snack products. Whether manufacturers are packaging nuts, chips, or candies, a fully automatic capping machine can be easily adjusted to accommodate different packaging requirements. This flexibility allows snack manufacturers to streamline their production processes and adapt to changing market demands.

In addition to speed, accuracy, and versatility, fully automatic screw capping machines also offer significant cost savings. By automating the capping process, manufacturers can reduce the need for manual labor and minimize the risk of human error. This not only improves the overall efficiency of the packaging line but also helps to reduce waste and rework. Furthermore, the durability and reliability of these machines mean that they require minimal maintenance, further reducing operating costs in the long run.

Overall, the benefits of using a fully automatic snacks plastic jar screw capping machine are clear. From increased speed and accuracy to improved versatility and cost savings, these machines offer snack manufacturers a range of advantages that can help them stay competitive in the market. By investing in a fully automatic capping machine, snack manufacturers can streamline their packaging operations, improve product quality, and ultimately enhance the overall customer experience.

How to Choose the Right Fully Automatic Snacks Plastic Jar Screw Capping Machine for Your Business

In the food industry, packaging plays a crucial role in maintaining the quality and freshness of products. When it comes to packaging snacks in plastic jars, having a reliable screw capping machine is essential. Fully automatic snacks plastic jar screw capping machines are designed to streamline the packaging process, ensuring efficiency and consistency in sealing the jars. However, with so many options available in the market, choosing the right machine for your business can be a daunting task. In this article, we will discuss some key factors to consider when selecting a fully automatic snacks plastic jar screw capping machine.

First and foremost, it is important to consider the size and shape of the plastic jars that you will be using for packaging. Different capping machines are designed to accommodate specific jar sizes and shapes, so make sure to choose a machine that is compatible with your packaging requirements. Additionally, consider the production capacity of the machine. If you have a high volume of jars to cap, you will need a machine that can keep up with your production demands.

Another important factor to consider is the type of caps that your plastic jars require. Fully automatic snacks plastic jar screw capping machines come with different types of capping heads, such as chuck cappers, spindle cappers, and snap cappers. Each type of capping head is designed for specific cap styles, so choose a machine that is suitable for the caps you will be using. Additionally, consider the torque requirements of your caps to ensure that the machine can apply the necessary amount of force to achieve a secure seal.

When selecting a fully automatic snacks plastic jar screw capping machine, it is also important to consider the level of automation that you require. Some machines come with advanced features such as automatic cap feeding, cap sorting, and cap tightening, while others offer basic capping functionality. Determine the level of automation that best suits your production needs and budget.

Furthermore, consider the overall build quality and durability of the capping machine. Look for machines that are made from high-quality materials and are built to withstand the rigors of continuous use in a production environment. A reliable and durable machine will not only ensure consistent capping results but also minimize downtime and maintenance costs in the long run.

In addition to the machine itself, it is important to consider the after-sales support and service provided by the manufacturer. Choose a reputable supplier that offers comprehensive training, technical support, and spare parts availability to ensure that your capping machine remains operational and efficient.

In conclusion, selecting the right fully automatic snacks plastic jar screw capping machine is crucial for ensuring the quality and efficiency of your packaging process. Consider factors such as jar size and shape, cap type, production capacity, level of automation, build quality, and after-sales support when making your decision. By choosing a machine that meets your specific requirements and quality standards, you can streamline your packaging process and enhance the overall productivity of your business.

Maintenance Tips for Fully Automatic Snacks Plastic Jar Screw Capping Machine

Maintaining a fully automatic snacks plastic jar screw capping machine is essential to ensure its optimal performance and longevity. Regular maintenance not only prevents breakdowns and costly repairs but also helps in maintaining the quality of the capped jars. In this article, we will discuss some important maintenance tips for a fully automatic snacks plastic jar screw capping machine.

First and foremost, it is important to regularly clean the machine to prevent any build-up of dirt, debris, or food particles. This can be done by wiping down the machine with a damp cloth and using a mild detergent to remove any stubborn stains. It is also important to clean the capping heads and the conveyor belts to ensure smooth operation.

In addition to regular cleaning, it is important to lubricate the moving parts of the machine to prevent wear and tear. This can be done by applying a small amount of lubricant to the capping heads, conveyor belts, and other moving parts. It is important to use the right type of lubricant for each part to prevent damage.

Another important maintenance tip is to regularly check the alignment of the capping heads. Misaligned capping heads can cause uneven capping and lead to leaks or spills. It is important to check the alignment of the capping heads regularly and adjust them if necessary.

It is also important to regularly check the tension of the conveyor belts. Loose conveyor belts can cause jars to fall off or get stuck, leading to production delays and wastage. It is important to check the tension of the conveyor belts regularly and adjust them if necessary.

Regularly inspecting the machine for any signs of wear and tear is also important. This includes checking for loose or damaged parts, worn-out belts, and any other signs of damage. It is important to replace any worn-out or damaged parts immediately to prevent further damage to the machine.

It is also important to regularly calibrate the machine to ensure accurate capping. This can be done by following the manufacturer’s instructions for calibration and making any necessary adjustments. Regular calibration ensures that the machine is capping jars accurately and prevents any issues with the capping process.

Lastly, it is important to train your staff on how to properly operate and maintain the fully automatic snacks plastic jar screw capping machine. Proper training ensures that the machine is used correctly and that maintenance tasks are carried out effectively. It is important to provide ongoing training to ensure that your staff is up to date on the latest maintenance procedures.

In conclusion, maintaining a fully automatic snacks plastic jar screw capping machine is essential to ensure its optimal performance and longevity. By following these maintenance tips, you can prevent breakdowns, costly repairs, and ensure that your machine continues to cap jars accurately and efficiently. Regular cleaning, lubrication, alignment checks, tension checks, inspection for wear and tear, calibration, and staff training are all important aspects of maintaining a fully automatic snacks plastic jar screw capping machine.