Benefits of Using a Fully Automatic Cocoa Powder Vacuum Nitrogen Flushing Metal Can Sealing Machine

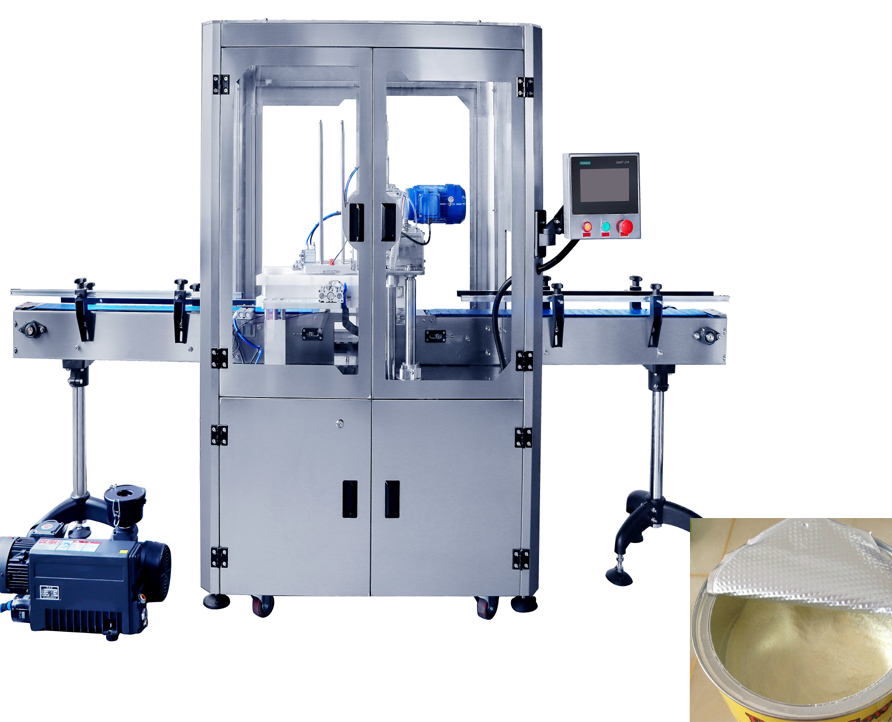

In the food industry, packaging plays a crucial role in preserving the quality and freshness of products. When it comes to packaging cocoa powder, it is essential to ensure that the packaging process is efficient and effective. One of the best ways to achieve this is by using a fully automatic cocoa powder vacuum nitrogen flushing metal can sealing machine.

This machine is designed to streamline the packaging process by automating the sealing of metal cans filled with cocoa powder. By using a vacuum nitrogen flushing system, this machine helps to remove oxygen from the cans, which is essential for preserving the quality of the cocoa powder. Additionally, the metal can sealing process ensures that the cocoa powder is protected from external contaminants, such as moisture and air.

One of the key benefits of using a fully automatic cocoa powder vacuum nitrogen flushing metal can sealing machine is the efficiency it brings to the packaging process. With this machine, companies can seal a large number of cans in a short amount of time, reducing the need for manual labor and increasing productivity. This not only saves time but also reduces the risk of human error, ensuring that the cocoa powder is sealed properly every time.

Furthermore, the vacuum nitrogen flushing system used in this machine helps to extend the shelf life of the cocoa powder. By removing oxygen from the cans, the machine creates an oxygen-free environment that helps to prevent oxidation and preserve the freshness of the cocoa powder. This is essential for ensuring that the cocoa powder maintains its flavor and quality for a longer period, ultimately increasing customer satisfaction.

Another benefit of using a fully automatic cocoa powder vacuum nitrogen flushing metal can sealing machine is the cost savings it offers. By automating the sealing process, companies can reduce the need for manual labor, which can be costly and time-consuming. Additionally, the machine helps to minimize waste by ensuring that the cocoa powder is properly sealed and protected from external contaminants. This not only reduces the risk of product spoilage but also helps to minimize the need for resealing or repackaging, saving companies money in the long run.

Moreover, the fully automatic nature of this machine makes it easy to operate and maintain. With user-friendly controls and a simple design, companies can easily integrate this machine into their packaging process without the need for extensive training or specialized knowledge. This helps to streamline operations and ensure that the packaging process runs smoothly and efficiently.

In conclusion, the benefits of using a fully automatic cocoa powder vacuum nitrogen flushing metal can sealing machine are numerous. From increased efficiency and cost savings to extended shelf life and ease of operation, this machine offers a range of advantages for companies in the food industry. By investing in this machine, companies can improve their packaging process, preserve the quality of their cocoa powder, and ultimately enhance customer satisfaction.