In the bustling world of canning industries, precision is the key to success. Whether it’s food, beverages, or other consumer products, a well – sealed can is essential for maintaining product quality, safety, and shelf – life. The automatic servo can seaming machine has emerged as a revolutionary tool that unlocks the full potential of precision in the can seaming process.

Table of Contents

The Essence of Precision in Can Seaming

Can seaming is not just about closing a can; it’s about creating a hermetic seal that protects the contents from external contaminants, oxygen, and moisture. A poorly sealed can can lead to spoilage, leakage, and a significant loss of product quality. Precision in can seaming ensures that the double – seam formed between the can body and the lid is consistent, tight, and meets the highest industry standards.

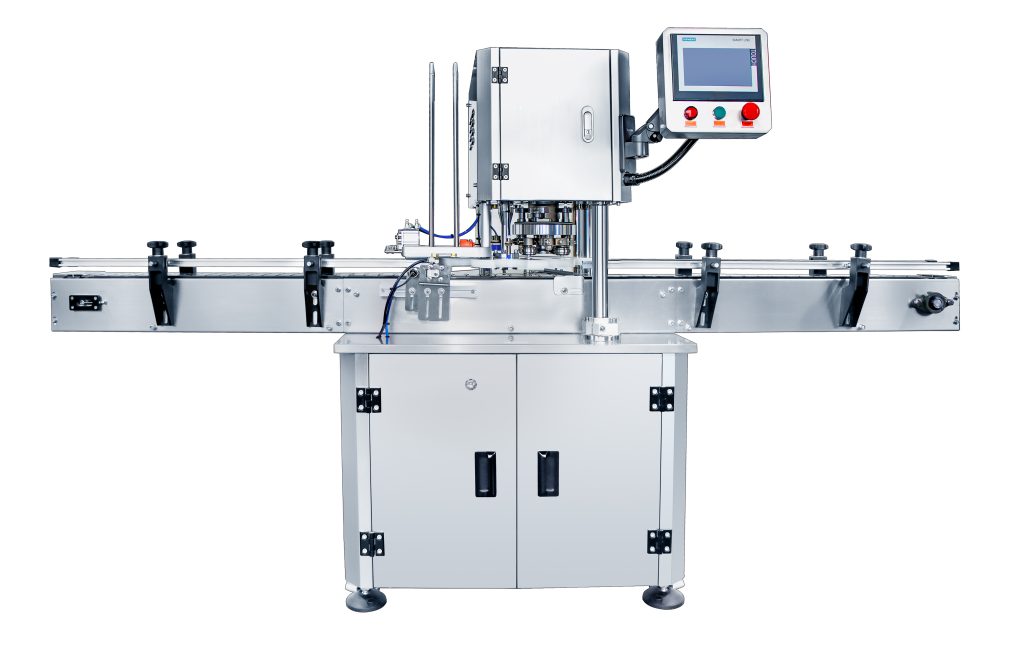

The automatic servo can seaming machine achieves this level of precision through its advanced servo – driven technology. Servo motors offer precise control over the seaming process, allowing for accurate adjustments of speed, force, and position. This means that each can, regardless of its size or the type of product it contains, is seamed with the exact same level of quality.

How Precision is Achieved

Advanced Sensor Technology

The machine is equipped with a variety of sensors that continuously monitor the seaming process. These sensors can detect even the slightest variations in parameters such as pressure, temperature, and the position of the can and lid. For example, pressure sensors ensure that the right amount of force is applied during the seaming operation. If the pressure is too low, the seam may not be tight enough; if it’s too high, it could damage the can or the product inside.

Real – Time Adjustments

Based on the data collected by the sensors, the automatic servo can seaming machine can make real – time adjustments to the seaming process. The servo motors can quickly respond to any deviations from the set parameters, ensuring that the seam quality remains consistent throughout the production run. This ability to adapt in real – time is a significant advantage over traditional can seaming methods, which often rely on manual adjustments and may not be as accurate.

Precise Can and Lid Handling

The machine also features precise can and lid handling mechanisms. It can accurately position the can and the lid before the seaming process begins, ensuring that the double – seam is formed correctly. This is crucial for achieving a high – quality seal, especially for cans with irregular shapes or non – standard sizes.

Benefits of Precision Seaming

Enhanced Product Quality

A precise seam means that the product inside the can is better protected. For food products, it helps to preserve the flavor, texture, and nutritional value. In the beverage industry, it prevents carbonation loss and maintains the freshness of the drink. This leads to higher customer satisfaction and a stronger brand reputation.

Extended Shelf – Life

A well – sealed can has a longer shelf – life. By preventing the entry of oxygen and moisture, the automatic servo can seaming machine helps to slow down the spoilage process. This reduces product waste and allows businesses to store and distribute their products for longer periods without compromising quality.

Reduced Production Costs

Precision seaming also leads to reduced production costs. Fewer defective cans mean less product loss and lower rework rates. Additionally, the machine’s high – speed operation and consistent performance increase overall production efficiency, allowing businesses to produce more cans in less time.

Conclusion

The automatic servo can seaming machine is a powerful tool that brings the power of precision to the canning industry. Its advanced technology, real – time adjustments, and precise handling mechanisms ensure that each can is seamed with the highest level of quality. By unleashing this precision, businesses can enhance product quality, extend shelf – life, and reduce production costs. In a competitive market, investing in an automatic servo can seaming machine is not just an option; it’s a necessity for those who want to stay ahead of the curve.