In the world of nut packaging, the can closing machine with nitrogen flushing is a revolutionary technology.

This specialized machine offers several significant benefits when it comes to preserving the quality and freshness of nuts. The nitrogen flushing process is a key feature that sets it apart.

Nitrogen, an inert gas, displaces the oxygen inside the can. By reducing the oxygen content, the growth of aerobic microorganisms and the rate of oxidation are greatly slowed down. This helps to extend the shelf life of the nuts, keeping them fresh and crunchy for a longer time.

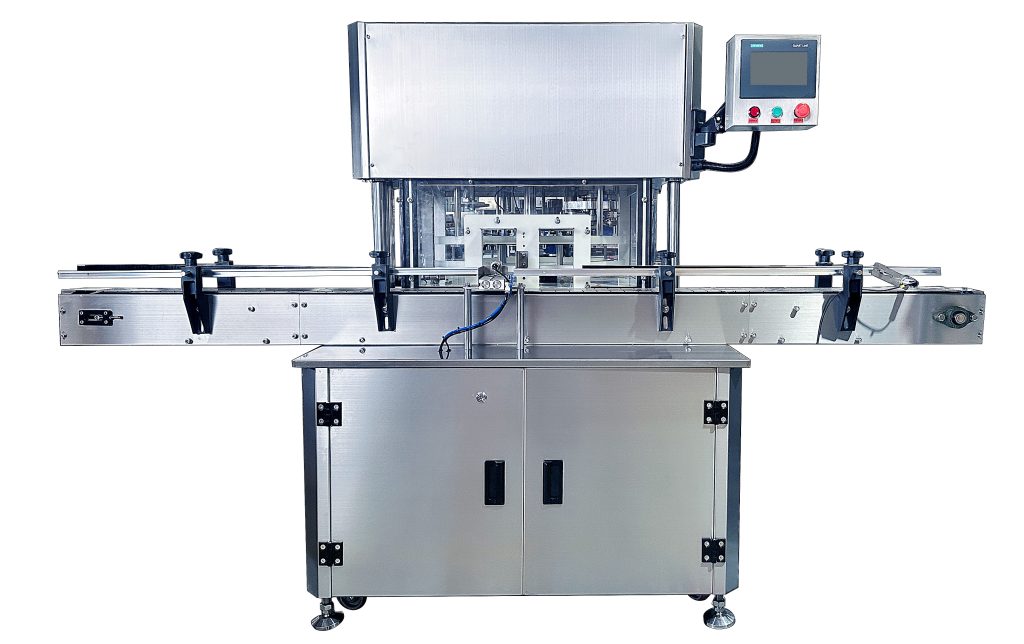

The can closing function of the machine ensures a tight and secure seal. This not only prevents any leakage but also protects the nuts from external contaminants such as moisture and air.

One of the major advantages of this machine is its ability to maintain the flavor and nutritional value of the nuts. Oxidation can cause nuts to become rancid and lose their taste and nutrients. With nitrogen flushing, nuts retain their original flavor and goodness.

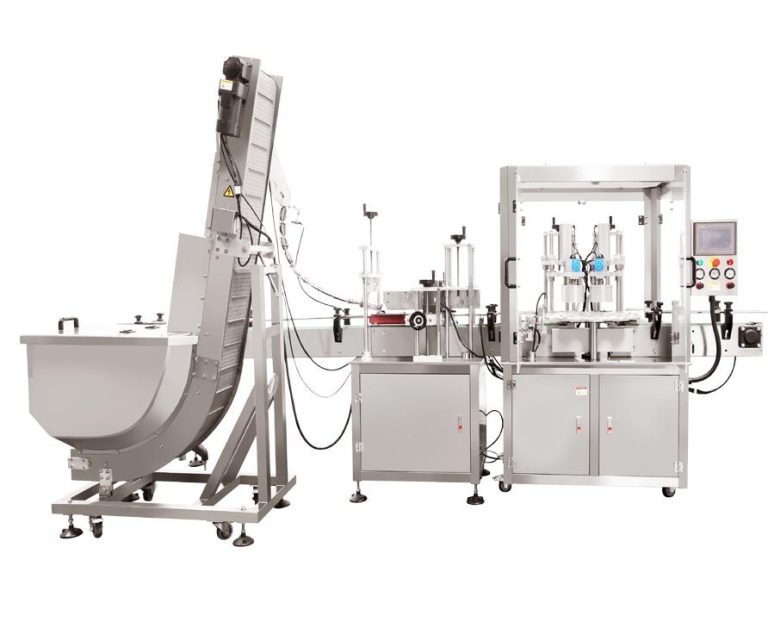

The machine is also designed for efficiency and speed. It can handle a large volume of cans in a short period, making it suitable for both small-scale and large-scale nut producers.

It is highly customizable, allowing for adjustments to accommodate different can sizes and nut varieties. This flexibility ensures that it can meet the specific packaging needs of various nut products.

In terms of quality control, the machine is equipped with sensors and monitoring systems to ensure that each can is properly filled, flushed with nitrogen, and sealed.

Overall, the can closing machine with nitrogen flushing is a game-changer in the packaging of nuts, providing a reliable and effective solution for maintaining product quality and satisfying consumer expectations.

Stay tuned to our blogs for more detailed insights and updates on the latest advancements in packaging technologies for food products!