It seems we can’t find what you’re looking for. Perhaps searching can help.

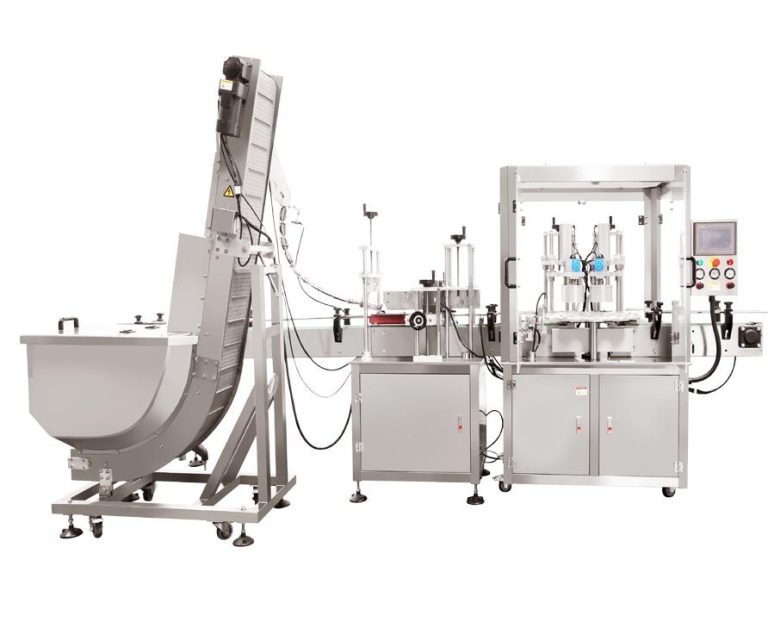

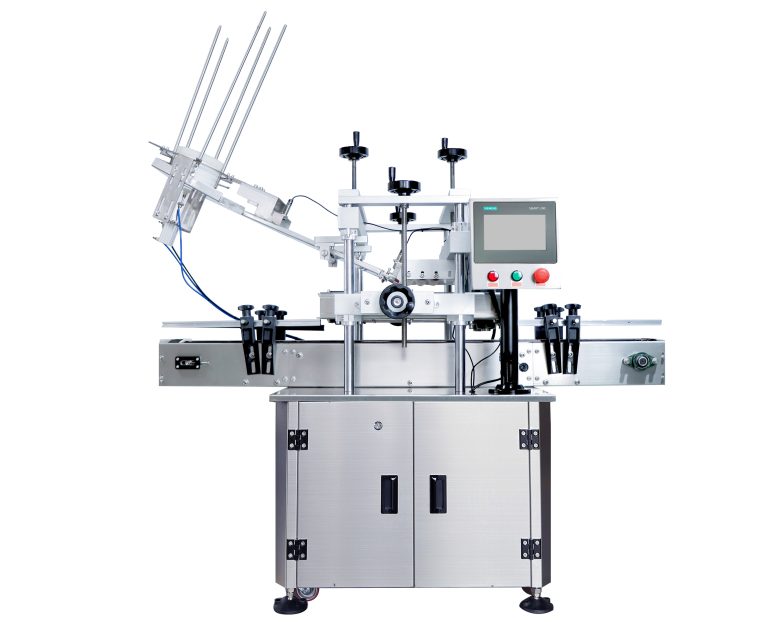

Seafood can filler packing line

Benefits of Using a Seafood Can Filler Packing Line Seafood can filler packing lines are essential equipment for seafood processing plants looking to efficiently package their products. These automated systems offer a range of benefits that can help streamline operations and improve overall productivity. One of the key advantages of…