It seems we can’t find what you’re looking for. Perhaps searching can help.

“Top 5 Benefits of Using a Semi-Automatic Nitrogen Can Sealing Machine”

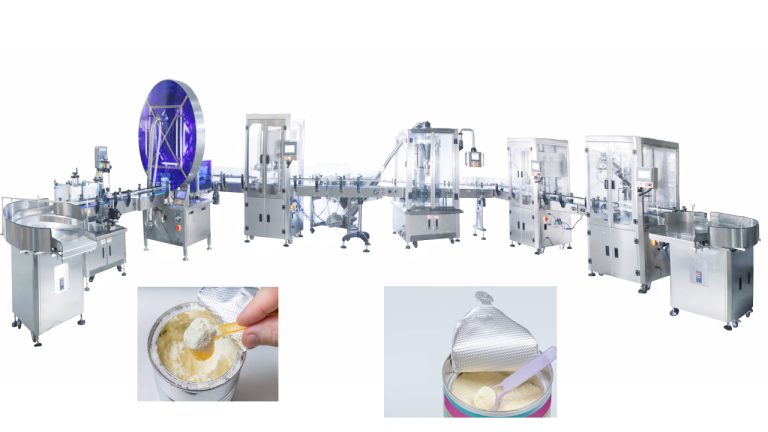

When it comes to can sealing, the semi-automatic nitrogen can sealing machine offers several significant advantages. Here are the top 5 benefits: Extended Shelf Life: By filling the cans with nitrogen before sealing, these machines create an inert environment that slows down the oxidation process. This helps to preserve the…