Table of Contents

Benefits of Automating Powder Can Packing Lines

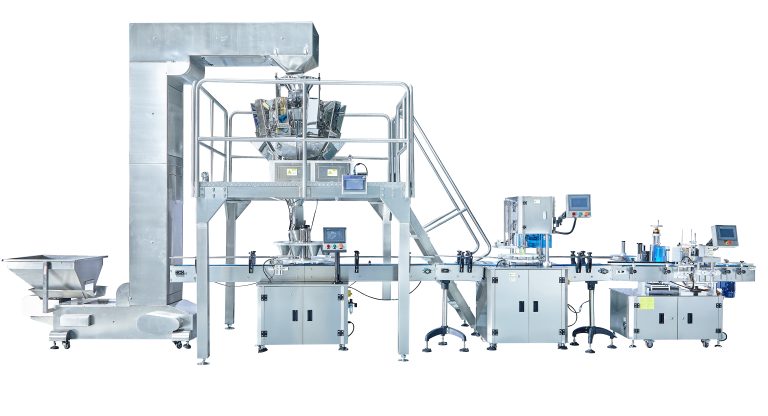

In today’s fast-paced manufacturing industry, efficiency and productivity are key factors in staying competitive. One area where companies can significantly improve their operations is in automating their powder can packing lines. By implementing automated systems, businesses can streamline their processes, reduce labor costs, and increase overall output.

One of the primary benefits of automating a powder can packing line is the increase in efficiency. Automated systems are designed to perform repetitive tasks quickly and accurately, resulting in a higher throughput compared to manual labor. This means that companies can pack more cans in less time, ultimately increasing their production capacity and meeting customer demand more effectively.

In addition to efficiency, automation also helps to reduce labor costs. By replacing manual labor with machines, companies can eliminate the need for multiple employees to perform packing tasks. This not only saves on labor expenses but also reduces the risk of human error, resulting in a more consistent and reliable packing process.

Furthermore, automated powder can packing lines are designed to be versatile and adaptable to different packaging requirements. Whether a company is packing cans of various sizes or shapes, automated systems can be easily adjusted to accommodate different products. This flexibility allows businesses to quickly switch between different packaging configurations without the need for extensive retooling or downtime.

Another key benefit of automating powder can packing lines is the improvement in product quality. Automated systems are equipped with sensors and monitoring devices that ensure each can is packed correctly and securely. This reduces the risk of damaged or improperly packed products, resulting in higher customer satisfaction and fewer returns.

Moreover, automation can also help to improve workplace safety. By removing employees from potentially hazardous packing tasks, companies can reduce the risk of workplace injuries and create a safer working environment for their employees. This not only protects the well-being of workers but also helps to minimize downtime and costly insurance claims.

Overall, automating powder can packing lines offers numerous benefits for companies looking to improve their operations. From increased efficiency and productivity to reduced labor costs and improved product quality, automation can help businesses stay competitive in today’s fast-paced manufacturing industry. By investing in automated systems, companies can streamline their packing processes, increase output, and ultimately achieve greater success in the market.

In conclusion, the benefits of automating powder can packing lines are clear. By implementing automated systems, companies can improve efficiency, reduce labor costs, enhance product quality, and create a safer working environment for their employees. With the right automation solutions in place, businesses can stay ahead of the competition and achieve long-term success in the industry.

Tips for Optimizing Efficiency in Powder Can Packing Lines

Powder can packing lines are essential in the manufacturing industry for efficiently packaging powdered products into cans. To ensure optimal efficiency in these packing lines, it is important to implement certain tips and strategies. By following these tips, manufacturers can streamline their operations, increase productivity, and reduce downtime.

One key tip for optimizing efficiency in powder can packing lines is to invest in high-quality equipment. This includes can filling machines, conveyors, and sealing machines that are reliable and durable. By using top-of-the-line equipment, manufacturers can minimize the risk of breakdowns and ensure smooth operation of the packing line.

Another important tip is to regularly maintain and calibrate the equipment. This includes cleaning the machines, checking for wear and tear, and ensuring that all components are functioning properly. By performing routine maintenance, manufacturers can prevent unexpected breakdowns and prolong the lifespan of their equipment.

In addition to maintaining the equipment, it is also crucial to train operators on how to use the packing line effectively. Proper training can help operators understand the intricacies of the equipment, troubleshoot issues, and operate the machines efficiently. By investing in training programs for operators, manufacturers can improve overall productivity and reduce the risk of errors on the packing line.

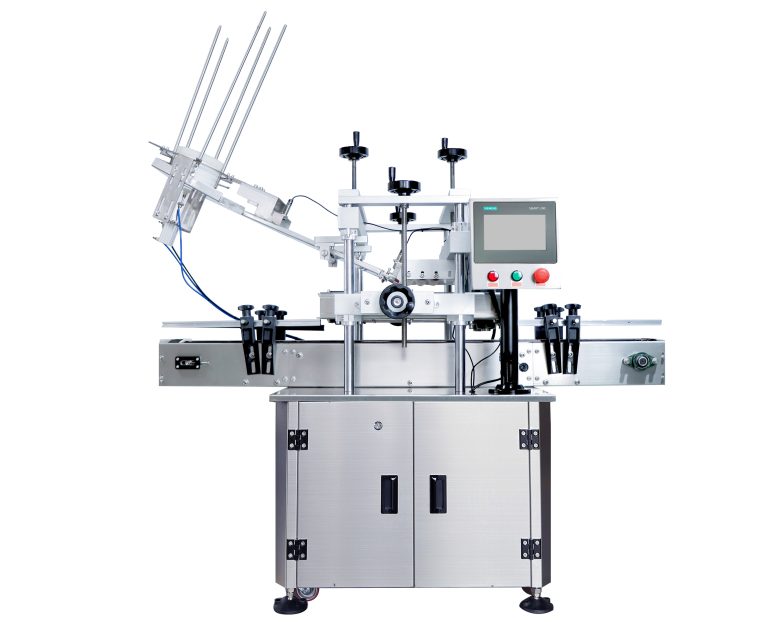

Furthermore, implementing automation and robotics can significantly enhance efficiency in powder can packing lines. Automated systems can perform repetitive tasks quickly and accurately, reducing the need for manual labor and increasing throughput. By incorporating automation into the packing line, manufacturers can improve speed, accuracy, and consistency in packaging powdered products.

To further optimize efficiency, manufacturers should also consider implementing a quality control system. This system can help identify defects, inconsistencies, or errors in the packaging process, allowing for immediate corrective action. By monitoring quality throughout the packing line, manufacturers can ensure that only high-quality products are being packaged and shipped to customers.

Moreover, utilizing data analytics and monitoring systems can provide valuable insights into the performance of the packing line. By tracking key performance indicators such as throughput, downtime, and error rates, manufacturers can identify areas for improvement and make data-driven decisions to optimize efficiency. By leveraging data analytics, manufacturers can continuously improve their packing line operations and maximize productivity.

Lastly, it is important to regularly review and optimize the layout of the packing line. By organizing the equipment in a logical and efficient manner, manufacturers can minimize unnecessary movements, reduce bottlenecks, and improve overall flow. By optimizing the layout of the packing line, manufacturers can enhance efficiency and streamline operations.

In conclusion, optimizing efficiency in powder can packing lines requires a combination of high-quality equipment, regular maintenance, operator training, automation, quality control, data analytics, and layout optimization. By implementing these tips and strategies, manufacturers can improve productivity, reduce downtime, and enhance overall performance in their packing operations. By continuously striving for efficiency and innovation, manufacturers can stay competitive in the market and meet the demands of their customers.