Table of Contents

Benefits of Using an Automatic Servo Can Closing Machine

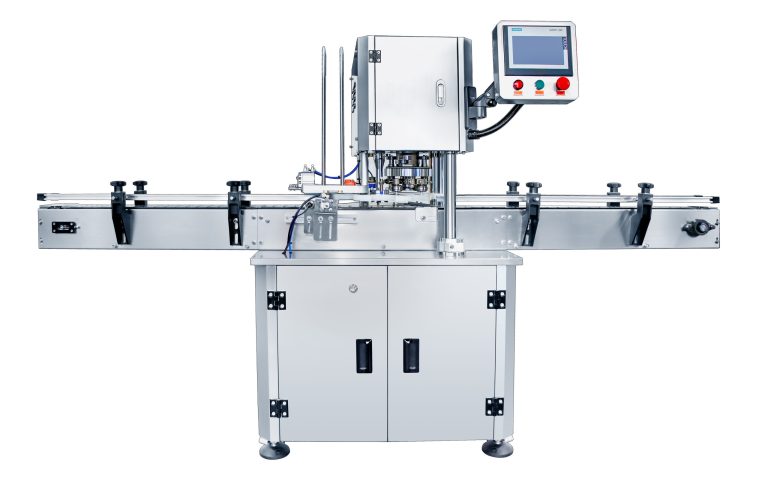

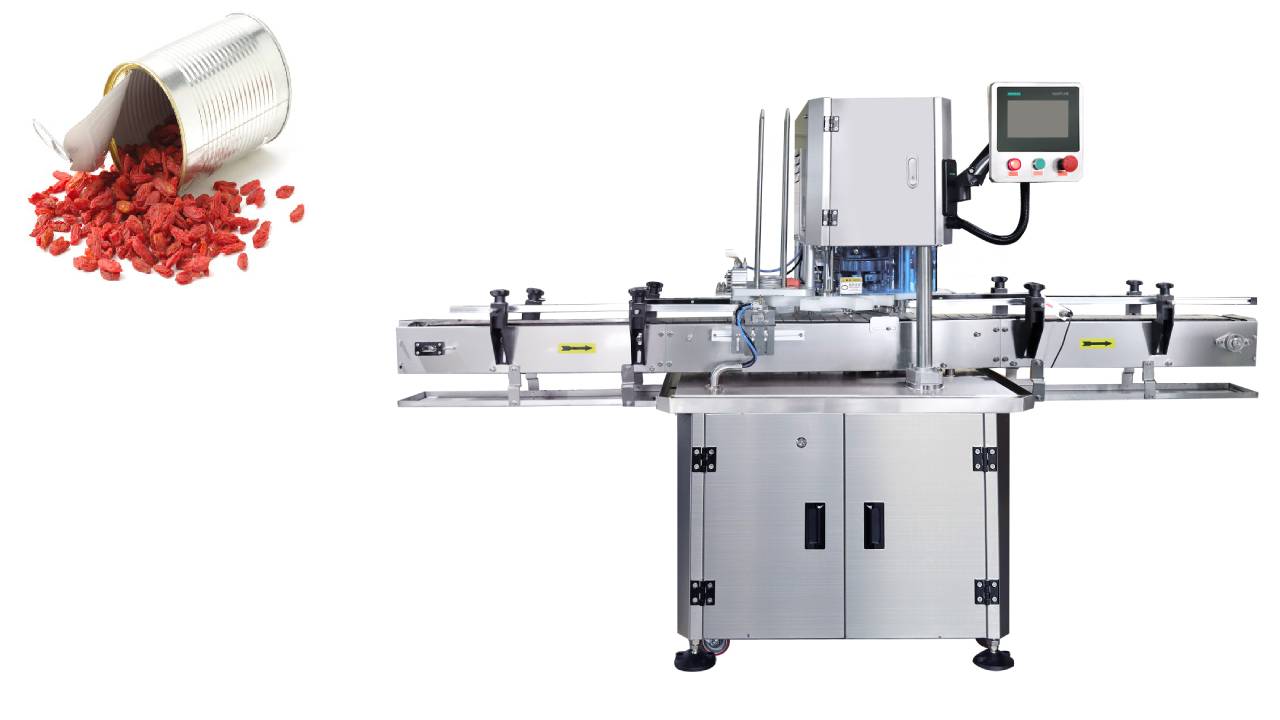

In the food industry, efficiency and precision are key factors in ensuring the quality and safety of products. One important aspect of food packaging is the sealing of cans, which helps to preserve the contents and prevent contamination. Traditionally, can closing has been done manually or with semi-automatic machines, but with advancements in technology, automatic servo can closing machines have become a popular choice for many food manufacturers.

One of the main benefits of using an automatic servo can closing machine is the speed and consistency it offers. These machines are equipped with servo motors that allow for precise control of the can closing process, resulting in a uniform and secure seal every time. This not only saves time but also reduces the risk of human error, ensuring that the cans are properly sealed and ready for distribution.

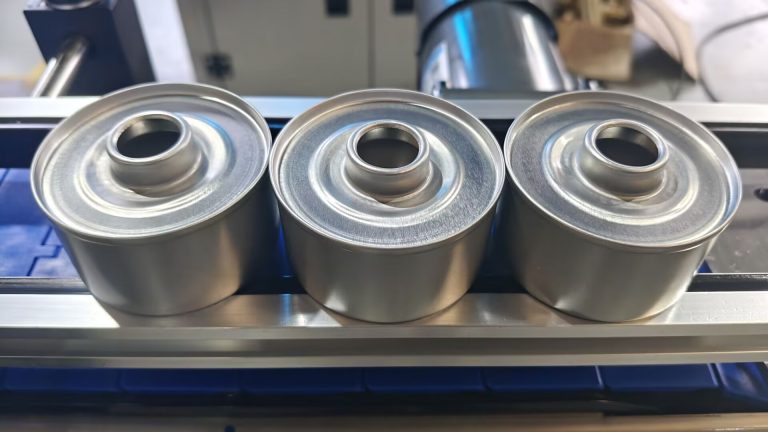

Another advantage of automatic servo can closing machines is their versatility. These machines can be easily adjusted to accommodate different can sizes and types, making them suitable for a wide range of products. Whether you are packaging soups, fruits, or vegetables, an automatic servo can closing machine can be customized to meet your specific needs, allowing for greater flexibility in production.

In addition to speed and versatility, automatic servo can closing machines also offer improved safety and hygiene. By automating the can closing process, the risk of contamination from human contact is minimized, ensuring that the products remain safe for consumption. Furthermore, these machines are designed to meet strict food safety standards, with features such as stainless steel construction and easy-to-clean surfaces that help to maintain a sanitary production environment.

Cost-effectiveness is another key benefit of using an automatic servo can closing machine. While the initial investment may be higher than manual or semi-automatic machines, the long-term savings in labor costs and increased productivity make it a worthwhile investment for many food manufacturers. By streamlining the can closing process and reducing the need for manual labor, these machines can help to improve overall efficiency and profitability.

Furthermore, automatic servo can closing machines are designed to be user-friendly, with intuitive controls and easy maintenance procedures. This makes it easy for operators to learn how to use the machine effectively and keep it running smoothly, minimizing downtime and maximizing productivity. With proper training and support, food manufacturers can fully optimize the performance of their automatic servo can closing machine, ensuring consistent and reliable results.

In conclusion, the benefits of using an automatic servo can closing machine for canned food packaging are clear. From improved speed and consistency to enhanced safety and hygiene, these machines offer a range of advantages that can help food manufacturers to optimize their production processes and deliver high-quality products to consumers. With the right investment and support, an automatic servo can closing machine can be a valuable asset for any food packaging operation.

How Automatic Servo Can Closing Machines Improve Efficiency in Canned Food Production

In the world of food production, efficiency is key. Companies are constantly looking for ways to streamline their processes and increase productivity. One area where efficiency can be greatly improved is in the closing of cans for canned food products. Traditional can closing methods can be time-consuming and labor-intensive, leading to bottlenecks in production. However, with the advent of automatic servo can closing machines, companies can now significantly improve their efficiency and output.

Automatic servo can closing machines are a type of packaging machinery that is designed to automatically close cans with precision and speed. These machines use servo motors to control the movement of the can closing mechanism, ensuring that each can is sealed tightly and securely. This not only improves the quality of the final product but also reduces the risk of contamination or spoilage.

One of the key benefits of automatic servo can closing machines is their speed. These machines are capable of closing cans at a much faster rate than manual methods, allowing companies to increase their production output significantly. This can be especially beneficial for companies that have high demand for their canned food products or need to meet tight deadlines.

Another advantage of automatic servo can closing machines is their accuracy. These machines are programmed to close cans with precision, ensuring that each can is sealed correctly every time. This helps to reduce the risk of leaks or other packaging issues, which can lead to product spoilage or customer complaints. By using automatic servo can closing machines, companies can improve the overall quality of their canned food products and enhance customer satisfaction.

In addition to speed and accuracy, automatic servo can closing machines also offer increased flexibility. These machines can be easily adjusted to accommodate different can sizes and types, making them suitable for a wide range of canned food products. This flexibility allows companies to quickly switch between different products without the need for extensive retooling or downtime, further improving efficiency in the production process.

Furthermore, automatic servo can closing machines are easy to operate and maintain. These machines are equipped with user-friendly interfaces that allow operators to quickly set up and adjust the machine as needed. Additionally, automatic servo can closing machines are designed to be durable and reliable, requiring minimal maintenance to keep them running smoothly. This helps to reduce downtime and ensure that production runs smoothly and efficiently.

Overall, automatic servo can closing machines offer a range of benefits that can greatly improve efficiency in canned food production. From increased speed and accuracy to enhanced flexibility and ease of operation, these machines are a valuable asset for companies looking to streamline their packaging processes. By investing in automatic servo can closing machines, companies can boost their productivity, improve the quality of their products, and ultimately increase their bottom line.

Maintenance Tips for Automatic Servo Can Closing Machines

Automatic servo can closing machines are essential equipment in the food packaging industry, ensuring that canned food products are sealed securely and efficiently. To maintain the optimal performance of these machines, it is crucial to follow a regular maintenance schedule. In this article, we will discuss some key maintenance tips for automatic servo can closing machines to help prolong their lifespan and prevent costly breakdowns.

One of the most important maintenance tasks for automatic servo can closing machines is regular cleaning. Over time, dust, debris, and food particles can accumulate on the machine’s components, leading to decreased efficiency and potential malfunctions. It is recommended to clean the machine thoroughly after each production run, paying special attention to areas where food residue is likely to build up. Use a mild detergent and a soft cloth to wipe down the surfaces, being careful not to damage any sensitive parts.

In addition to cleaning, lubrication is another crucial aspect of maintenance for automatic servo can closing machines. Proper lubrication helps reduce friction between moving parts, preventing wear and tear and ensuring smooth operation. It is important to use the correct type of lubricant recommended by the machine’s manufacturer and to apply it to the designated areas according to the maintenance manual. Over-lubrication can be just as harmful as under-lubrication, so be sure to follow the guidelines carefully.

Regular inspection of the machine’s components is also essential to identify any potential issues before they escalate into major problems. Check for loose or damaged parts, worn-out seals, and signs of corrosion. Replace any faulty components immediately to prevent further damage to the machine and ensure its continued reliability. It is a good idea to keep a record of all inspections and repairs for future reference.

Calibration is another important maintenance task for automatic servo can closing machines. Over time, the machine’s settings may drift out of alignment, affecting the quality of the seals on the cans. Regularly calibrating the machine according to the manufacturer’s specifications will help maintain consistent performance and prevent product wastage. If you are unsure how to calibrate the machine, consult the maintenance manual or contact the manufacturer for assistance.

Lastly, it is crucial to train your staff on proper machine operation and maintenance procedures. A well-trained operator can help identify issues early on and perform routine maintenance tasks effectively. Provide regular training sessions to ensure that your staff is up to date on the latest maintenance techniques and safety protocols. Encourage open communication between operators and maintenance personnel to address any concerns or issues promptly.

In conclusion, regular maintenance is key to ensuring the optimal performance and longevity of automatic servo can closing machines. By following these maintenance tips, you can prevent costly breakdowns, minimize downtime, and extend the lifespan of your equipment. Remember to clean, lubricate, inspect, calibrate, and train your staff regularly to keep your machine running smoothly and efficiently. Your investment in maintenance will pay off in the long run with increased productivity and reduced maintenance costs.