Table of Contents

Benefits of Using Automatic Milk Powder Can Vacuum Closing Machine with N2 Flushing

In the food industry, particularly in the production of milk powder, packaging plays a crucial role in maintaining the quality and freshness of the product. One of the key components in ensuring the longevity of milk powder is the sealing process. This is where automatic milk powder can vacuum closing machines with N2 flushing come into play.

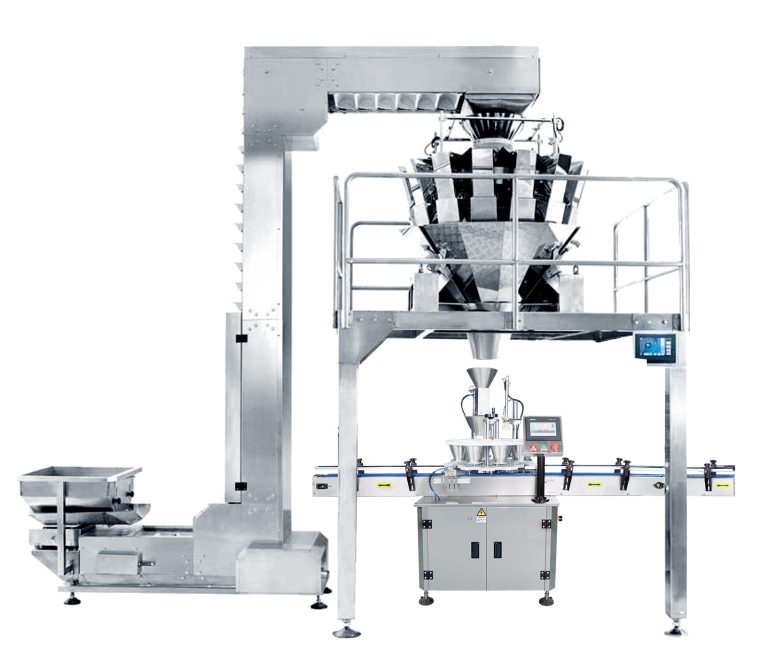

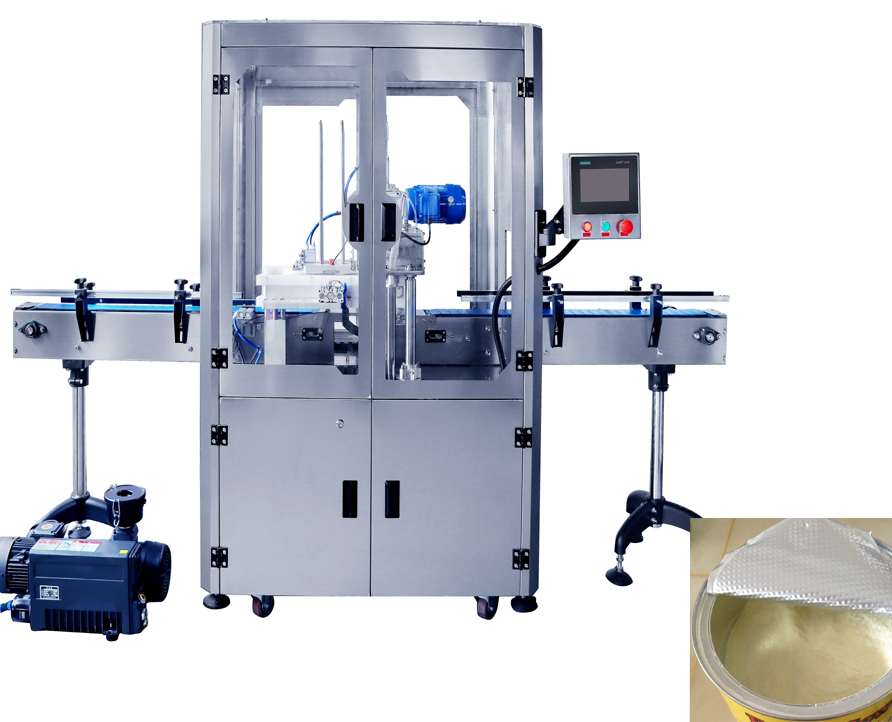

These machines are designed to automatically seal cans of milk powder by creating a vacuum inside the can and flushing it with nitrogen gas. This process helps to remove oxygen from the can, which is essential for preserving the quality of the milk powder. Oxygen can lead to oxidation, which can cause the milk powder to spoil and lose its nutritional value.

By using an automatic milk powder can vacuum closing machine with N2 flushing, manufacturers can extend the shelf life of their product and ensure that it reaches consumers in optimal condition. This not only benefits the consumers by providing them with a high-quality product but also benefits the manufacturers by reducing waste and increasing customer satisfaction.

One of the key benefits of using an automatic milk powder can vacuum closing machine with N2 flushing is the improved shelf life of the product. By removing oxygen from the can and replacing it with nitrogen gas, the machine helps to create a protective barrier that prevents oxidation and spoilage. This can significantly extend the shelf life of the milk powder, allowing manufacturers to store and distribute their product for longer periods without compromising its quality.

In addition to extending the shelf life of the product, automatic milk powder can vacuum closing machines with N2 flushing also help to maintain the freshness and flavor of the milk powder. Oxygen can cause the milk powder to become rancid and develop off-flavors over time. By removing oxygen from the can, the machine helps to preserve the freshness and flavor of the milk powder, ensuring that consumers receive a product that tastes as good as it did when it was first packaged.

Furthermore, using an automatic milk powder can vacuum closing machine with N2 flushing can also help to improve the overall quality of the product. By creating a vacuum inside the can, the machine helps to remove any excess air or moisture that may be present, which can lead to clumping or caking of the milk powder. This results in a smoother and more uniform product that is easier to dissolve and mix, providing consumers with a better overall experience.

Overall, the benefits of using an automatic milk powder can vacuum closing machine with N2 flushing are clear. From extending the shelf life of the product to maintaining its freshness and flavor, these machines play a crucial role in ensuring the quality of milk powder for consumers. By investing in this technology, manufacturers can improve the quality of their product, reduce waste, and increase customer satisfaction.

How to Choose the Right Automatic Milk Powder Can Vacuum Closing Machine with N2 Flushing for Your Business

When it comes to packaging milk powder, ensuring that the product remains fresh and free from contaminants is crucial. One way to achieve this is by using an automatic milk powder can vacuum closing machine with N2 flushing. This type of machine not only seals the cans tightly to prevent air and moisture from entering but also flushes the cans with nitrogen gas to further protect the product from oxidation.

There are several factors to consider when choosing the right automatic milk powder can vacuum closing machine with N2 flushing for your business. One of the most important considerations is the size and capacity of the machine. You will need to determine how many cans you need to seal per hour and choose a machine that can meet your production requirements. Additionally, consider the size of the cans you will be using and make sure that the machine is compatible with them.

Another important factor to consider is the level of automation that the machine offers. Some machines are fully automatic and require minimal human intervention, while others may require more manual labor. Depending on your production needs and budget, you will need to decide which level of automation is right for your business.

It is also important to consider the quality and reliability of the machine. Look for a machine that is made from high-quality materials and has a reputation for durability. You want a machine that will be able to withstand the rigors of daily use and continue to perform reliably over time.

In addition to the machine itself, consider the level of customer support and service that the manufacturer offers. Look for a company that provides excellent customer service and is responsive to any issues or concerns that may arise. Having a reliable manufacturer to turn to for support can make a big difference in the long-term success of your business.

When choosing an automatic milk powder can vacuum closing machine with N2 flushing, it is also important to consider the cost. While it may be tempting to choose the cheapest option available, it is important to remember that quality and reliability are key factors in ensuring the success of your business. Consider the long-term costs of maintenance and repairs, as well as the potential for increased productivity and efficiency with a higher-quality machine.

In conclusion, choosing the right automatic milk powder can vacuum closing machine with N2 flushing for your business is a crucial decision that can have a significant impact on the quality and success of your product. Consider factors such as size and capacity, level of automation, quality and reliability, customer support, and cost when making your decision. By taking the time to carefully evaluate your options and choose a machine that meets your specific needs, you can ensure that your milk powder remains fresh and protected, and your business thrives.