In the enchanting world of chocolate production, where every detail matters, the automatic chocolate box sealing machine stands out as a true magician. It weaves its magic with precision and speed, transforming the mundane task of sealing chocolate boxes into a seamless and efficient process. Let’s take a behind – the – scenes look at how this remarkable machine works its charm.

Table of Contents

The Entrance of the Chocolate Boxes

Conveyor Belt Transport

The journey begins as chocolate boxes are placed onto a conveyor belt. This conveyor belt serves as the stage for the entire sealing performance. It gently carries the boxes towards the heart of the machine at a steady pace. The speed of the conveyor can be adjusted according to the production requirements, ensuring a smooth and continuous flow of boxes.

Alignment and Positioning

Before the boxes reach the sealing area, they go through an alignment process. Special sensors and guides ensure that each box is perfectly positioned. This is crucial because even a slight misalignment can affect the quality of the seal. The machine’s precision in aligning the boxes is like a meticulous choreographer arranging dancers on a stage.

The Tape Preparation

Tape Dispensing

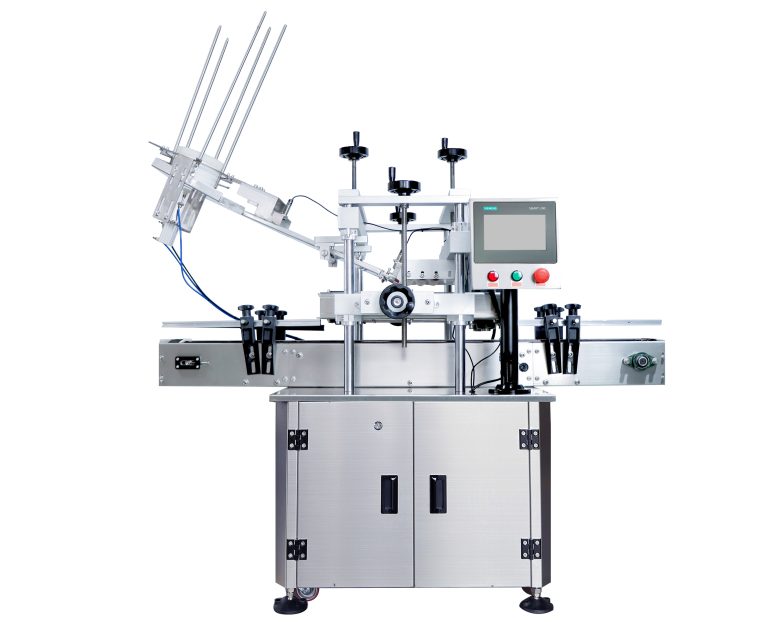

The automatic chocolate box sealing machine is equipped with a tape dispenser. This dispenser holds a large roll of sealing tape, which is usually made of high – quality adhesive material. The tape is fed from the roll and guided through a series of rollers and guides. These components ensure that the tape is pulled smoothly and evenly, ready to be applied to the boxes.

Tape Cutting Mechanism

As the tape is dispensed, a cutting mechanism is in place to cut the tape to the appropriate length for each box. This mechanism uses a sharp blade that can make clean and precise cuts. The length of the tape is determined by the size of the box, and the machine can be programmed to adjust the cutting length accordingly.

The Sealing Process

Top and Bottom Sealing

Once the box is in the sealing position, the machine starts its magic. It first applies the tape to the top of the box. The tape is pressed firmly against the box’s surface, creating a strong and secure seal. Then, the box is flipped over (in some models) or the sealing mechanism moves to the bottom of the box to apply the tape there as well. This double – sided sealing ensures that the chocolates inside are well – protected from air, moisture, and dust.

Pressure Application

To ensure a tight seal, the machine applies pressure to the tape as it is being applied. Special pressure pads or rollers press down on the tape, forcing it to adhere firmly to the box. The amount of pressure can be adjusted to suit different types of boxes and tapes, ensuring optimal sealing results.

The Exit and Quality Control

Exit Conveyor

After the sealing process is complete, the chocolate box is sent on its way down another conveyor belt. This exit conveyor takes the sealed boxes to the next stage of the production process, such as labeling or packaging into larger cartons.

Quality Inspection

Some automatic chocolate box sealing machines are equipped with quality inspection systems. These systems use sensors to check the quality of the seal. They can detect if the tape is applied correctly, if there are any gaps or bubbles in the seal, or if the tape has been cut to the right length. If a box fails the quality inspection, it can be automatically diverted from the production line for further inspection or re – sealing.

The Charm in Efficiency and Consistency

High – Speed Operation

One of the most impressive aspects of the automatic chocolate box sealing machine is its high – speed operation. It can seal a large number of boxes in a short period of time, far exceeding the capabilities of manual sealing. This high – speed performance allows chocolate manufacturers to increase their production output and meet the demands of the market.

Consistent Sealing Quality

Every box that passes through the machine receives the same high – quality seal. The machine’s precision and automation ensure that the tape is applied evenly and tightly every time. This consistency is essential for maintaining the brand image of the chocolate products. Customers expect their chocolates to be well – packaged, and the automatic sealing machine delivers on that expectation.

In conclusion, the automatic chocolate box sealing machine is truly a magic tape – wrapper. Its ability to handle the sealing process with speed, precision, and consistency is a game – changer for the chocolate industry. It not only makes the production process more efficient but also enhances the overall quality and presentation of the chocolate products. So, the next time you open a beautifully sealed box of chocolates, you can appreciate the charm of the machine that made it possible.