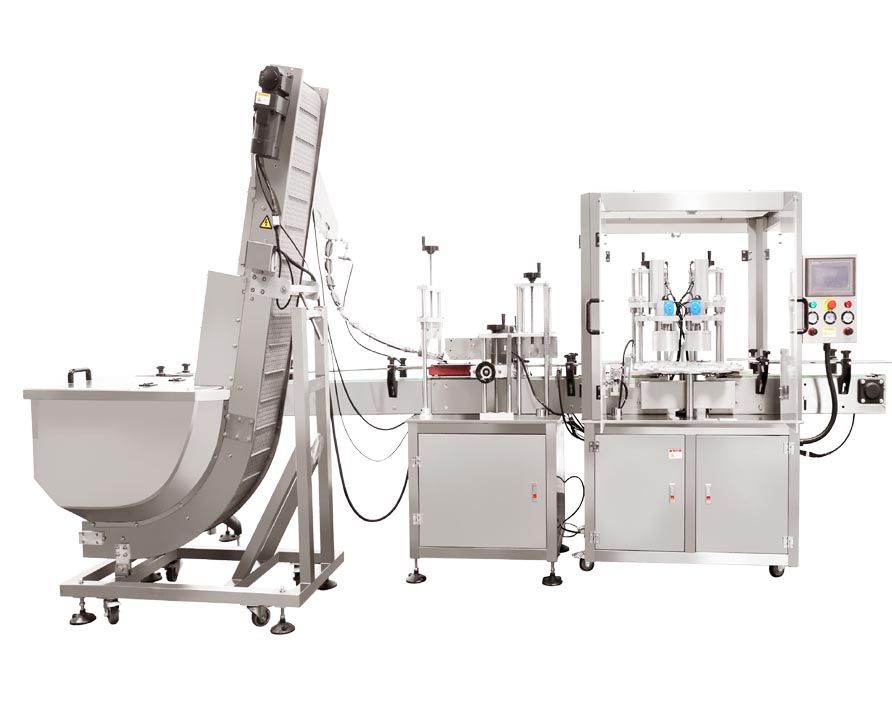

An Automatic Double-Head Glass Bottle Vacuum Capping Machine is a cutting-edge piece of equipment designed to streamline the capping process for glass bottles. This advanced machine is specifically engineered to handle the task of sealing glass bottles with precision and efficiency.

The machine features two capping heads, which significantly increases its productivity compared to single-head models. This dual-head configuration allows for simultaneous capping of multiple bottles, reducing the overall processing time.

The working mechanism of the Automatic Double-Head Glass Bottle Vacuum Capping Machine is quite fascinating. First, the glass bottles are placed on the conveyor belt or in a designated position. The machine then detects the presence of the bottles and positions the caps accurately over the bottle openings.

Next, a vacuum is created within the bottle. This vacuum helps to remove any air or gases present, ensuring a clean and airtight environment inside the bottle. Once the vacuum is established, the caps are firmly applied and sealed onto the bottle tops.

The force and pressure applied during the capping process are precisely controlled to guarantee a secure and consistent seal. The machine’s advanced sensors and control systems monitor and adjust the parameters in real-time to ensure optimal capping quality for each bottle.

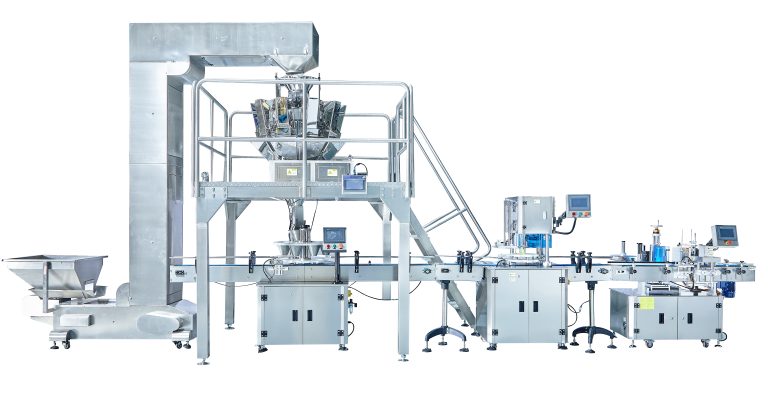

The combination of the double-head design and the vacuum sealing technology makes this machine highly efficient and reliable. It is capable of handling a large volume of glass bottles with consistent accuracy, making it an essential tool in industries such as food and beverage, pharmaceuticals, and cosmetics, where proper sealing and preservation of the contents are crucial.

In summary, the Automatic Double-Head Glass Bottle Vacuum Capping Machine is a sophisticated device that simplifies and enhances the capping process for glass bottles, providing a reliable and efficient solution for various industries.