In the ever-evolving landscape of industrial packaging and labeling, the emergence of the Automatic Single Side Labeling Machine has been nothing short of revolutionary. Let’s take a closer look at what makes this machine such a game-changer.

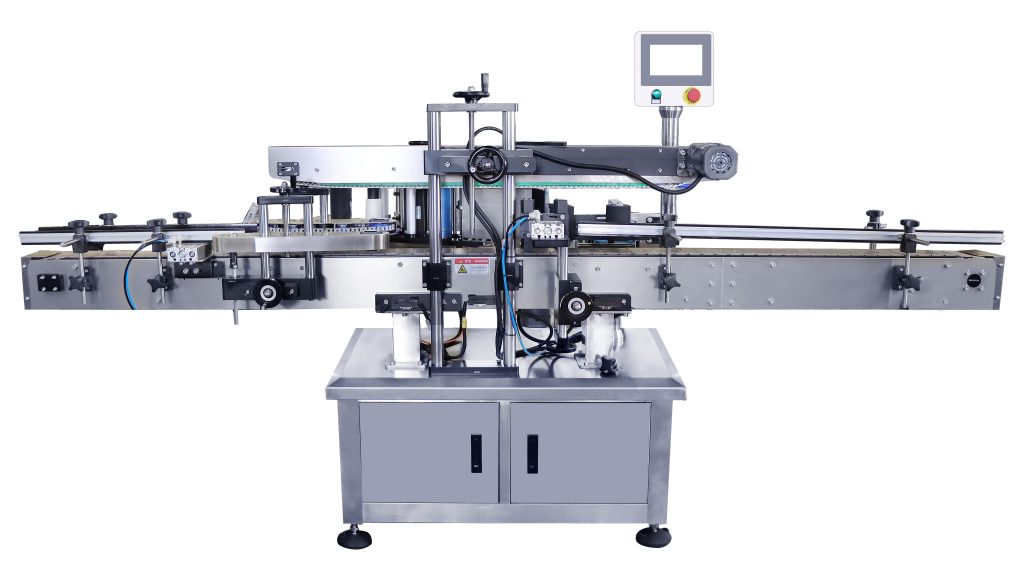

The first aspect that stands out is its cutting-edge technology. This machine is equipped with state-of-the-art sensors and software that ensure precise label placement with minimal margin of error. Every label is applied smoothly and accurately, enhancing the overall aesthetic appeal of the product.

The speed at which it operates is truly remarkable. It can handle a large volume of items in a short span of time, significantly boosting productivity on the factory floor. This increased efficiency not only saves time but also reduces labor costs, giving businesses a competitive edge.

Another notable feature is its adaptability. It can effortlessly handle a wide range of product shapes and sizes, from small vials to large containers. This flexibility makes it suitable for various industries, from pharmaceuticals to cosmetics and food and beverages.

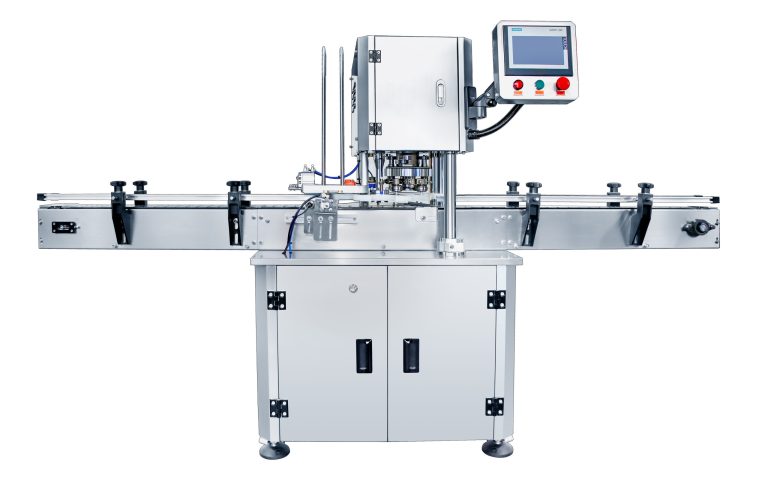

The machine’s user-friendly interface is also a major plus. Operators can easily program and monitor the labeling process, making adjustments on the fly to meet specific requirements. This simplicity in operation reduces the training time for new staff and ensures seamless integration into existing production lines.

Maintenance of the Automatic Single Side Labeling Machine is relatively straightforward. Regular upkeep is manageable, and the availability of spare parts ensures minimal downtime in case of any unexpected issues.

In conclusion, the Automatic Single Side Labeling Machine is not just a piece of equipment; it’s a revolutionary solution that transforms the way products are labeled. Its combination of advanced technology, speed, adaptability, and ease of use makes it an indispensable asset for any modern manufacturing facility.