Table of Contents

Introduction

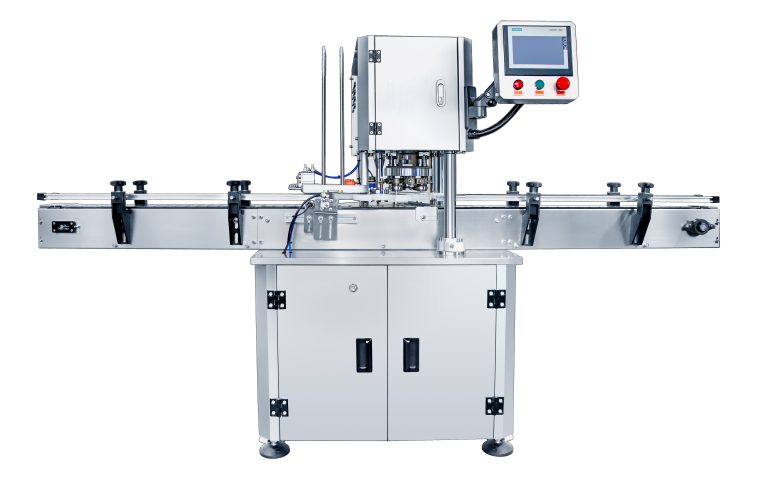

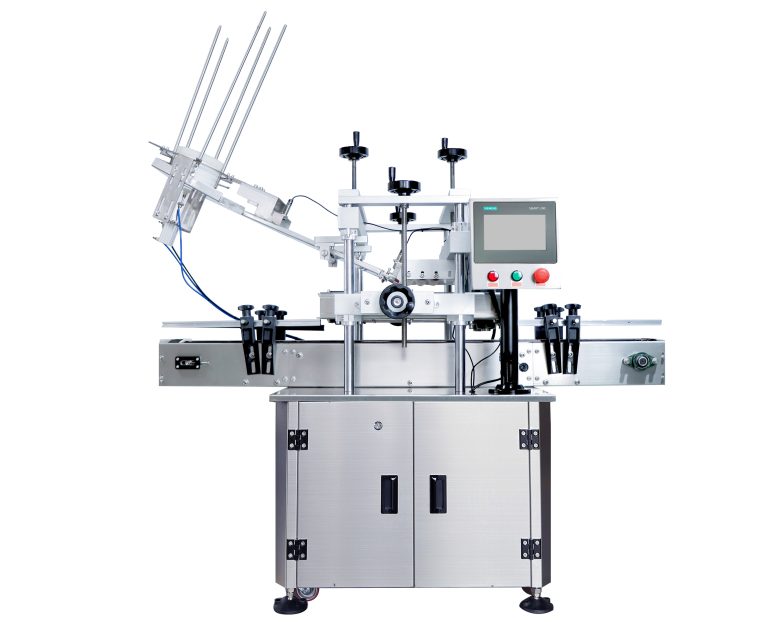

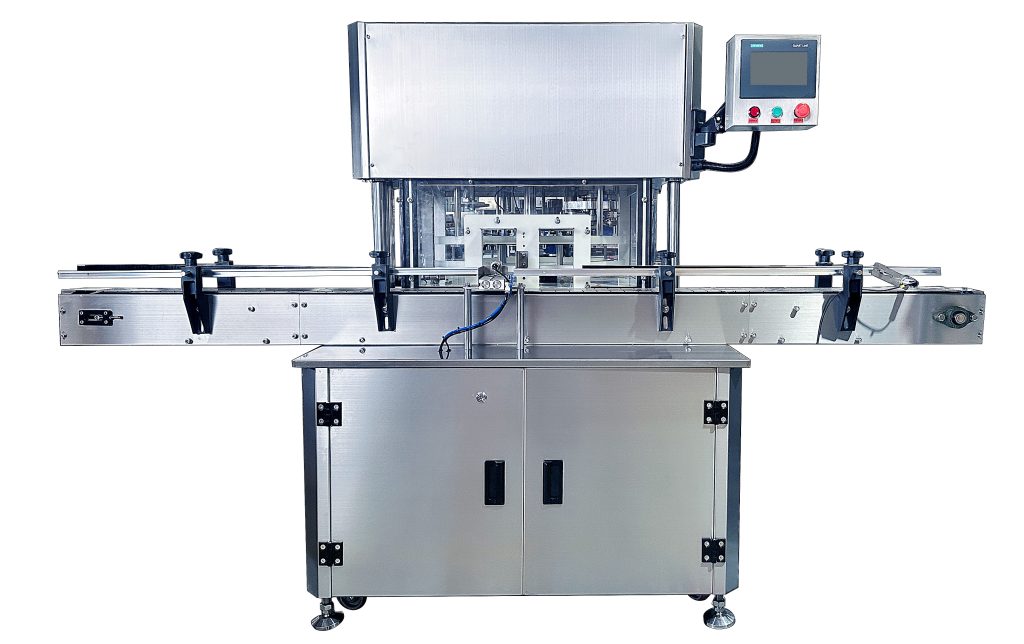

In the dried fruit industry, shelf – life is a critical factor that influences everything from production planning to consumer satisfaction. A longer shelf – life means reduced waste, expanded market reach, and higher profits. Enter the automatic dried fruit nitrogen flush can seamer, a technological marvel that can extend the shelf – life of dried fruits by an astonishing 90%. This article delves into how this innovative machine is transforming the dried fruit industry.

The Significance of Shelf – Life in the Dried Fruit Industry

Dried fruits are a popular snack and ingredient, known for their natural sweetness and nutritional value. However, they are also prone to spoilage over time. Oxidation, caused by exposure to oxygen, is one of the main culprits. It leads to the development of off – flavors, discoloration, and a loss of nutritional content.

For producers, a short shelf – life means they have to sell their products quickly or face significant losses. It also limits their ability to export to distant markets. Retailers, on the other hand, have to manage their inventory carefully to avoid having expired products on their shelves. And consumers are more likely to purchase dried fruits that have a longer shelf – life, as they can store them at home without worrying about them going bad.

How the Automatic Dried Fruit Nitrogen Flush Can Seamer Works

The automatic dried fruit nitrogen flush can seamer operates on a straightforward yet highly effective principle. First, the dried fruits are loaded into cans. Then, the machine uses a sophisticated system to introduce nitrogen gas into the cans. Nitrogen is an inert gas, which means it does not react with the dried fruits.

As the nitrogen is pumped in, it displaces the oxygen inside the can. Once the oxygen is removed, the can is sealed tightly. This creates an oxygen – free environment inside the can, which slows down the oxidation process and inhibits the growth of aerobic microorganisms that cause spoilage.

The 90% Shelf – Life Extension

The impact of the automatic nitrogen flush can seamer on the shelf – life of dried fruits is truly remarkable. Without this technology, dried fruits may have a shelf – life of a few months. But with the nitrogen flush, that shelf – life can be extended by up to 90%.

For example, consider a batch of dried cranberries. In a regular sealed container, they might start to show signs of spoilage within 3 – 4 months. But when preserved using the automatic nitrogen flush can seamer, they can remain fresh and delicious for 6 – 7 months or even longer. This extended shelf – life gives producers and retailers more time to sell the products and allows consumers to enjoy them over an extended period.

Transformation of the Dried Fruit Industry

For Producers

- Reduced Waste: With a longer shelf – life, producers can reduce the amount of dried fruits that go to waste due to spoilage. This directly translates into cost savings and increased profitability.

- Expanded Market Reach: They can now export their products to more distant markets without worrying about the fruits spoiling during transit. This opens up new business opportunities and helps them grow their customer base.

- Production Planning: Producers can plan their production more effectively. They can produce larger batches of dried fruits, knowing that they have more time to sell them.

For Retailers

- Inventory Management: Retailers can manage their inventory more easily. They don’t have to worry about constantly restocking dried fruits and can keep a larger stock on their shelves without the fear of expiration.

- Reduced Losses: Fewer expired products mean less financial loss for retailers. This also improves their bottom line and allows them to offer more competitive prices to consumers.

For Consumers

- Convenience: Consumers can buy dried fruits in larger quantities without having to worry about them going bad quickly. This is especially convenient for families or those who use dried fruits regularly in their cooking or baking.

- Quality Assurance: They can be confident that the dried fruits they purchase will retain their flavor, texture, and nutritional value for a longer time.

Conclusion

The automatic dried fruit nitrogen flush can seamer is a game – changer in the dried fruit industry. The 90% increase in shelf – life it provides has far – reaching benefits for producers, retailers, and consumers alike. As this technology becomes more widespread, it will continue to transform the way dried fruits are produced, sold, and consumed, making the industry more efficient, profitable, and sustainable.