It seems we can’t find what you’re looking for. Perhaps searching can help.

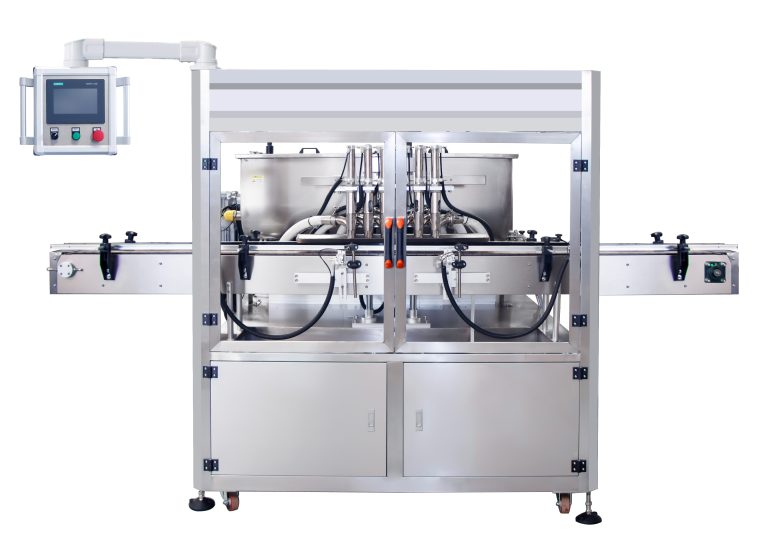

Hot Paste Viscous Liquid Filling Machine

Benefits of Using Hot Paste Viscous Liquid Filling Machine Hot paste viscous liquid filling machines are essential equipment for industries that deal with products such as sauces, creams, gels, and other viscous liquids. These machines offer a wide range of benefits that can significantly improve the efficiency and productivity of…