In the dynamic landscape of modern packaging, efficiency, precision, and adaptability are the cornerstones of success. The automatic 8 wheels screw capping machine has emerged as a revolutionary force, reshaping the way products are sealed and setting new standards in the industry.

Table of Contents

Precision Engineering for Flawless Sealing

At the heart of the automatic 8 wheels screw capping machine lies its remarkable precision. Each of the eight wheels is crafted with meticulous attention to detail, calibrated to apply the exact amount of torque required for a secure and consistent cap seal. This precision is essential, especially in industries where product integrity is paramount.

For example, in the food and beverage sector, a loose cap can lead to spoilage, while an over – tightened cap may damage the packaging or make it difficult for consumers to open. The machine’s ability to achieve the perfect seal every time ensures that products reach consumers in optimal condition, enhancing brand reputation and customer satisfaction.

High – Speed Efficiency

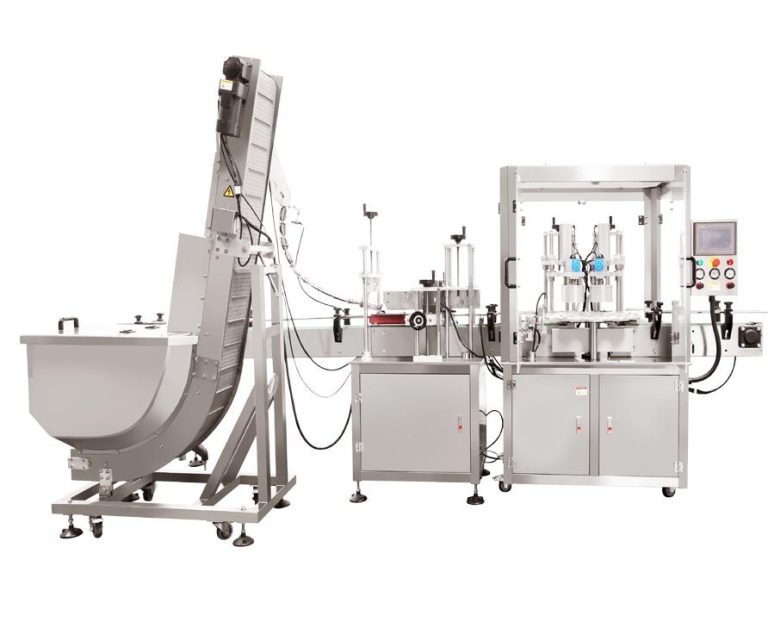

One of the most impressive features of the 8 wheels screw capping machine is its exceptional speed. With eight wheels working in unison, it can cap a large number of bottles or containers in a short period. This high – speed operation significantly boosts production throughput, allowing manufacturers to meet the ever – increasing demands of the market.

In a production line, time is money. The automatic nature of this machine means that it can operate continuously without the need for frequent manual intervention. It can be integrated seamlessly with other packaging equipment, creating a smooth and efficient workflow. This not only saves labor costs but also reduces the overall production time, giving businesses a competitive edge.

Versatile Capability

The automatic 8 wheels screw capping machine is incredibly versatile, capable of handling a wide variety of cap types and sizes. Whether it’s plastic caps, metal caps, or even caps with unique designs, the machine can adapt to different requirements.

This versatility is a game – changer for manufacturers who produce multiple product lines. Instead of investing in separate capping machines for each type of cap, they can rely on this single machine to handle them all. It can be easily adjusted to accommodate different cap dimensions and thread patterns, providing a cost – effective and flexible solution for packaging needs.

Advanced Technology Integration

The power of the automatic 8 wheels screw capping machine is further enhanced by its integration of advanced technologies. It is equipped with state – of the – art sensors and control systems that monitor the capping process in real – time.

These sensors can detect any abnormalities, such as misaligned caps or incorrect torque, and immediately take corrective action. The machine can also be programmed to store different capping parameters for various products, allowing for quick and easy setup changes. This level of automation and control ensures consistent quality and reduces the risk of human error.

A Sustainable Solution

In today’s environmentally conscious world, sustainability is an important consideration. The automatic 8 wheels screw capping machine contributes to sustainable packaging practices in several ways.

Firstly, its precision sealing reduces the likelihood of product waste due to improper capping. Secondly, its energy – efficient design helps to minimize power consumption during operation. By choosing this machine, manufacturers can not only improve their production processes but also make a positive impact on the environment.

In conclusion, the automatic 8 wheels screw capping machine is a powerful tool that offers a combination of precision, speed, versatility, and advanced technology. It has the potential to transform the packaging industry, enabling manufacturers to achieve higher levels of productivity, quality, and sustainability. As the demand for better – packaged products continues to grow, this machine will undoubtedly play a crucial role in shaping the future of packaging.

-768x512.jpg)

-768x622.jpg)