In an era where environmental consciousness is at the forefront of global concerns, sustainable packaging solutions have become a necessity for businesses. Automatic glass bottle vacuum capping machines are emerging as a key player in promoting sustainable packaging practices, offering a multitude of benefits for both the environment and the industry.

Table of Contents

The Environmental Advantages of Glass Bottles

Recyclability

Glass is one of the most recyclable materials on the planet. It can be recycled indefinitely without losing its quality or purity. When glass bottles are recycled, they are melted down and used to create new bottles, reducing the demand for raw materials such as sand, soda ash, and limestone. This not only conserves natural resources but also reduces the energy required for manufacturing new bottles. Automatic glass bottle vacuum capping machines are designed to work with glass bottles, facilitating their use in packaging and encouraging the recycling loop.

Durability

Glass bottles are highly durable and can withstand multiple uses. Unlike some plastic containers that may degrade or break after a few uses, glass bottles can be reused numerous times. This reusability factor significantly reduces waste generation. For example, in the beverage industry, returnable glass bottles can be refilled and recapped using automatic glass bottle vacuum capping machines, minimizing the need for single – use packaging.

Non – Toxicity

Glass is a non – toxic material that does not leach harmful chemicals into the products it contains. This makes it a safe choice for packaging food, beverages, and pharmaceuticals. In contrast, some plastics may release chemicals such as bisphenol A (BPA) into the contents, which can have negative health impacts. By using glass bottles with automatic capping machines, businesses can ensure that their products are packaged in a safe and environmentally friendly manner.

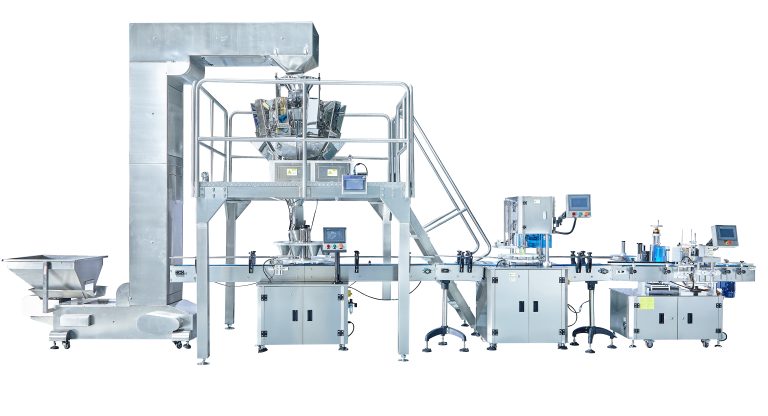

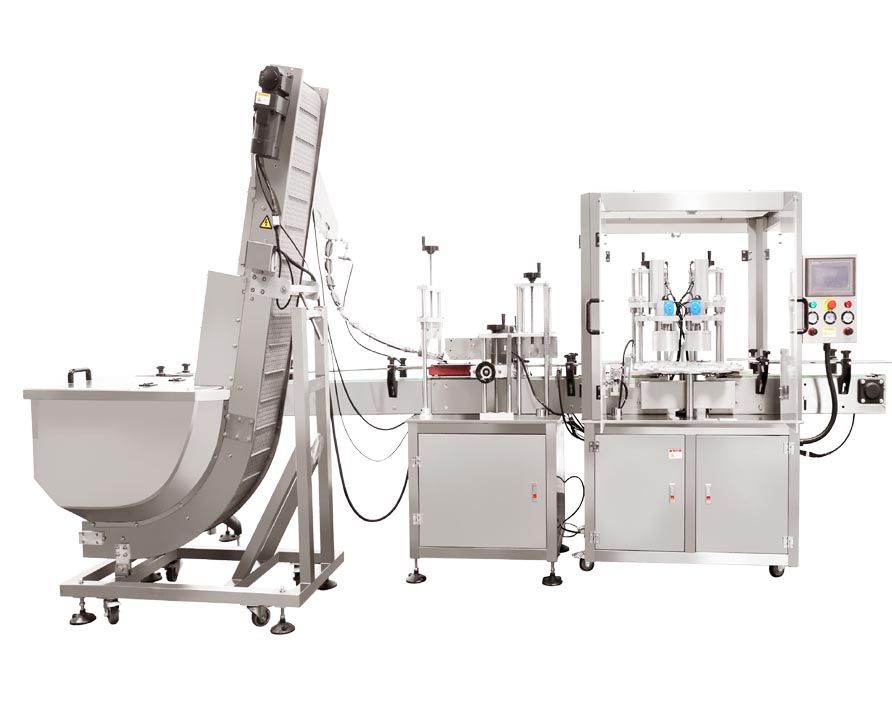

The Role of Automatic Vacuum Capping in Sustainability

Reducing Product Waste

Automatic glass bottle vacuum capping machines create a tight seal by removing the air from the bottle before capping. This vacuum environment helps to preserve the freshness and quality of the product inside the bottle. By extending the shelf – life of the product, it reduces the likelihood of spoilage and waste. For instance, in the food industry, products such as jams and sauces can last longer when properly vacuum – capped, reducing the amount of food that is discarded due to spoilage.

Energy Efficiency

These machines are designed to be energy – efficient. They are equipped with advanced technology that optimizes the vacuuming and capping processes, using less energy compared to older or less sophisticated capping methods. Additionally, the use of glass bottles in combination with automatic capping machines can lead to overall energy savings in the supply chain. Since glass bottles are heavier than some plastic alternatives, they may require more energy for transportation. However, the long – term energy savings from recycling and reusing glass bottles, as well as the reduced product waste, often outweigh the initial transportation energy costs.

Minimizing Packaging Materials

Automatic glass bottle vacuum capping machines can achieve a high – quality seal without the need for excessive packaging materials. Unlike some packaging methods that rely on additional layers of plastic or cardboard for protection and sealing, glass bottles with vacuum caps can provide a secure and protective enclosure with minimal extra materials. This reduction in packaging waste contributes to a more sustainable packaging solution.

Industry Adoption and Future Outlook

Many industries are increasingly recognizing the benefits of sustainable packaging with automatic glass bottle vacuum capping machines. The food and beverage industry, in particular, has been quick to adopt this technology. Craft breweries, wineries, and artisanal food producers are using these machines to package their products in an environmentally friendly way, appealing to consumers who are more conscious about sustainability.

Looking to the future, the demand for sustainable packaging solutions is only expected to grow. As technology continues to advance, automatic glass bottle vacuum capping machines will likely become even more efficient and versatile. They may be integrated with smart sensors and control systems to further optimize the capping process and reduce energy consumption. Additionally, the development of new glass materials and capping technologies may enhance the sustainability and performance of these machines, making them an even more attractive option for businesses committed to environmental responsibility.

In conclusion, automatic glass bottle vacuum capping machines offer a sustainable packaging solution that combines the environmental benefits of glass bottles with the efficiency and precision of automated technology. By reducing waste, conserving resources, and minimizing energy consumption, these machines play a crucial role in promoting a more sustainable future for the packaging industry.