Table of Contents

Benefits of Using Milk Powder in Large Diameter Tin Can Packaging

Milk powder has been a staple in many households for decades, providing a convenient and long-lasting alternative to fresh milk. With the rise in demand for milk powder, manufacturers are constantly looking for efficient and reliable ways to package and distribute this product. One popular method is using large diameter tin cans for packaging, which offer several benefits for both producers and consumers.

One of the main advantages of using large diameter tin cans for milk powder packaging is their durability. These cans are made of high-quality materials that can withstand the rigors of transportation and storage, ensuring that the product remains fresh and uncontaminated. This is especially important for milk powder, which can easily spoil if exposed to moisture or air. By using large diameter tin cans, producers can guarantee the quality of their product and build trust with consumers.

In addition to durability, large diameter tin cans also offer excellent protection against external elements such as light and heat. Milk powder is sensitive to these factors, which can degrade its quality over time. By packaging milk powder in large diameter tin cans, producers can shield the product from harmful UV rays and temperature fluctuations, ensuring that it retains its nutritional value and flavor for longer periods. This is particularly important for consumers who may not use the entire can of milk powder at once, as it allows them to store the product without worrying about spoilage.

Furthermore, large diameter tin cans are easy to stack and store, making them ideal for both producers and retailers. These cans can be neatly arranged on shelves or pallets, maximizing storage space and facilitating efficient inventory management. This is especially beneficial for manufacturers who produce large quantities of milk powder and need to store them in bulk. By using large diameter tin cans, producers can streamline their production process and reduce the risk of product damage or loss.

Another advantage of using large diameter tin cans for milk powder packaging is their versatility. These cans can be customized with various features such as easy-open lids, tamper-evident seals, and resealable closures, making them convenient for consumers to use. Additionally, large diameter tin cans can be printed with vibrant designs and branding, helping producers to differentiate their products on the market and attract more customers. This level of customization and branding can enhance the overall consumer experience and build brand loyalty over time.

In conclusion, the use of large diameter tin cans for milk powder packaging offers numerous benefits for both producers and consumers. From durability and protection to convenience and versatility, these cans provide a reliable and efficient solution for packaging and distributing milk powder. As the demand for milk powder continues to grow, manufacturers can rely on large diameter tin cans to meet the needs of their customers and deliver high-quality products that stand out in the market.

Step-by-Step Guide to Setting Up a Milk Powder Filling and Packaging Production Line

Milk powder is a popular dairy product that has a long shelf life and is convenient for storage and transportation. To meet the demand for milk powder, many companies are investing in large diameter tin can filling and packaging production lines. These production lines are designed to efficiently fill and package milk powder into tin cans of various sizes, ensuring that the product is sealed and protected from external contaminants.

Setting up a milk powder filling and packaging production line requires careful planning and attention to detail. The process involves several steps, from selecting the right equipment to ensuring that the production line meets industry standards for food safety and quality. In this article, we will provide a step-by-step guide to setting up a milk powder filling and packaging production line.

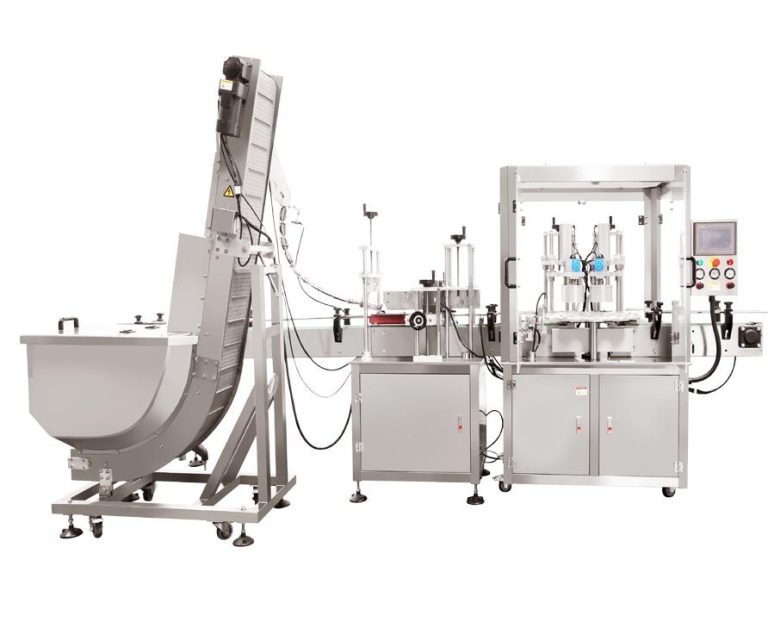

The first step in setting up a milk powder filling and packaging production line is to select the right equipment. This includes a filling machine, a sealing machine, a labeling machine, and a packaging machine. It is important to choose equipment that is suitable for filling and packaging milk powder in large diameter tin cans. The equipment should be easy to operate, maintain, and clean, and should meet industry standards for food safety and quality.

Once the equipment has been selected, the next step is to set up the production line. This involves arranging the equipment in the correct order and ensuring that each machine is properly connected and calibrated. It is important to test the production line before starting production to ensure that it is functioning correctly and that the milk powder is being filled and packaged accurately.

After the production line has been set up, the next step is to prepare the milk powder for filling and packaging. This involves ensuring that the milk powder is of high quality and free from contaminants. The milk powder should be stored in a clean and dry environment and should be handled with care to prevent contamination. It is important to follow industry standards for food safety and quality when handling milk powder.

Once the milk powder has been prepared, the next step is to start production. This involves operating the filling machine to fill the tin cans with the correct amount of milk powder, operating the sealing machine to seal the cans, operating the labeling machine to label the cans, and operating the packaging machine to package the cans for distribution. It is important to monitor the production line closely to ensure that the milk powder is being filled and packaged correctly and that the cans are sealed and labeled accurately.

After production is complete, the final step is to clean and maintain the production line. This involves cleaning the equipment, removing any leftover milk powder, and ensuring that the production line is ready for the next production run. It is important to follow industry standards for food safety and quality when cleaning and maintaining the production line.

In conclusion, setting up a milk powder filling and packaging production line requires careful planning and attention to detail. By following the steps outlined in this article, companies can ensure that their production line is efficient, safe, and meets industry standards for food safety and quality. With the right equipment, preparation, and maintenance, companies can successfully fill and package milk powder in large diameter tin cans for distribution to consumers.