Table of Contents

Benefits of Using a Fully Automatic Peanut Paste Can Filling and Seaming Machine

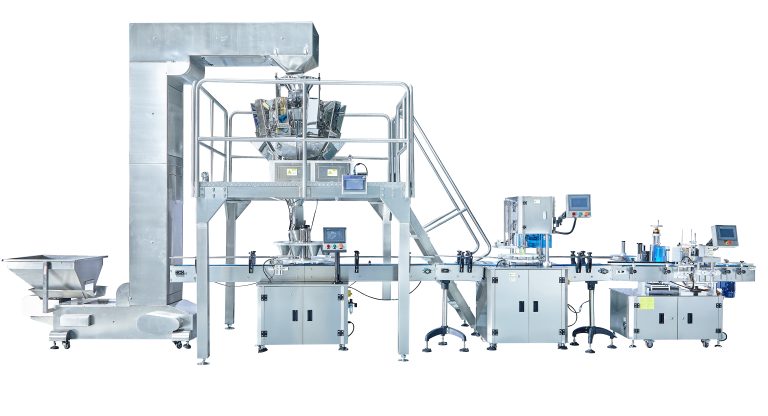

In the food industry, efficiency and consistency are key factors in ensuring the quality of products. One way to achieve this is by using fully automatic peanut paste can filling and seaming machines. These machines are designed to streamline the process of filling and sealing cans with peanut paste, providing numerous benefits for manufacturers.

One of the main advantages of using a fully automatic peanut paste can filling and seaming machine is the increase in production efficiency. These machines are capable of filling and sealing a large number of cans in a short amount of time, reducing the need for manual labor and increasing overall productivity. This not only saves time but also reduces the risk of human error, ensuring that each can is filled and sealed accurately and consistently.

Furthermore, fully automatic peanut paste can filling and seaming machines are equipped with advanced technology that allows for precise control over the filling process. This means that manufacturers can adjust the amount of peanut paste dispensed into each can, ensuring that the product meets the desired weight and consistency. This level of control is essential for maintaining the quality of the product and meeting the standards set by regulatory bodies.

Another benefit of using a fully automatic peanut paste can filling and seaming machine is the reduction in product waste. These machines are designed to minimize spillage and ensure that each can is filled to the correct level, reducing the amount of peanut paste that is wasted during the filling process. This not only helps to save costs but also contributes to a more sustainable production process.

In addition to efficiency and waste reduction, fully automatic peanut paste can filling and seaming machines also offer improved hygiene and safety benefits. These machines are designed to meet strict hygiene standards, with features such as stainless steel construction and easy-to-clean surfaces. This helps to prevent contamination and ensure that the product remains safe for consumption.

Furthermore, fully automatic peanut paste can filling and seaming machines are equipped with safety features that help to protect operators from potential hazards. These machines are designed to operate smoothly and efficiently, reducing the risk of accidents and injuries in the workplace. This not only ensures the safety of workers but also helps to maintain a positive working environment.

Overall, the benefits of using a fully automatic peanut paste can filling and seaming machine are clear. From increased production efficiency and reduced product waste to improved hygiene and safety, these machines offer numerous advantages for manufacturers in the food industry. By investing in this technology, manufacturers can streamline their production process, improve the quality of their products, and ultimately achieve greater success in the market.

How to Choose the Right Fully Automatic Peanut Paste Can Filling and Seaming Machine for Your Business

In the food industry, efficiency and precision are key factors in ensuring the success of a business. When it comes to packaging products such as peanut paste, having the right equipment can make all the difference. Fully automatic peanut paste can filling and seaming machines are essential for businesses looking to streamline their production process and increase output. These machines are designed to accurately fill cans with peanut paste and seal them securely, ensuring product freshness and quality.

When choosing a fully automatic peanut paste can filling and seaming machine for your business, there are several factors to consider. The first thing to look at is the capacity of the machine. Depending on the size of your operation and the demand for your product, you will need to choose a machine that can handle the volume of cans you need to fill and seal. It is important to choose a machine that can keep up with your production needs without causing bottlenecks in the process.

Another important factor to consider is the speed of the machine. Fully automatic peanut paste can filling and seaming machines come in a range of speeds, so it is important to choose one that can meet the demands of your production line. A machine that is too slow can lead to delays in production, while a machine that is too fast may not be able to fill and seal cans accurately. Finding the right balance is crucial to ensuring smooth and efficient operation.

In addition to capacity and speed, it is also important to consider the accuracy and precision of the machine. Fully automatic peanut paste can filling and seaming machines should be able to fill cans with the correct amount of product and seal them securely to prevent leaks and contamination. Look for machines that have precise filling mechanisms and reliable sealing systems to ensure the quality of your product.

When choosing a fully automatic peanut paste can filling and seaming machine, it is also important to consider the ease of operation and maintenance. Look for machines that are user-friendly and easy to clean and maintain. A machine that is difficult to operate or requires frequent maintenance can lead to downtime and increased costs. Choose a machine that is reliable and easy to use to keep your production line running smoothly.

Finally, consider the reputation of the manufacturer when choosing a fully automatic peanut paste can filling and seaming machine. Look for a manufacturer with a proven track record of producing high-quality machines that are reliable and durable. Reading reviews and testimonials from other customers can help you gauge the quality of the machine and the level of customer support provided by the manufacturer.

In conclusion, choosing the right fully automatic peanut paste can filling and seaming machine for your business is essential for ensuring smooth and efficient production. Consider factors such as capacity, speed, accuracy, ease of operation, and manufacturer reputation when making your decision. By investing in a high-quality machine that meets your production needs, you can streamline your operation and increase output, leading to greater success for your business.